Printer

Upgrade Your 3D Printing Game with Aluminum Extrusion Technology

Are you tired of the limitations of your current 3D printing setup? Do you want to take your creations to the next level? Then it’s time to upgrade your 3D printing game with aluminum extrusion technology.

Gone are the days of flimsy plastic frames and shaky builds. With aluminum extrusions, you can create strong, stable, and precise machines that can handle even the most complex designs. The strength of aluminum means you can print faster and with more accuracy than ever before.

But it’s not just about the quality of your prints. Aluminum extrusion technology also allows for customization and flexibility in design, making it easier to adjust and adapt your printer to meet your specific needs. Plus, with the added durability and longevity of aluminum, your printer will last longer and require less maintenance.

So don’t settle for mediocrity in your 3D printing journey. Upgrade to aluminum extrusion technology and unlock endless possibilities for your creations. Read on to learn more about how to make the switch and take your 3D printing skills to new heights.

“3d Printer Aluminum Extrusion” ~ bbaz

Introduction

3D printing has come a long way since its inception in the 1980s. With advancements in technology, the process has become more accessible, affordable and convenient. One of the most recent additions to the 3D printing world is aluminum extrusion technology.

What is Aluminum Extrusion Technology?

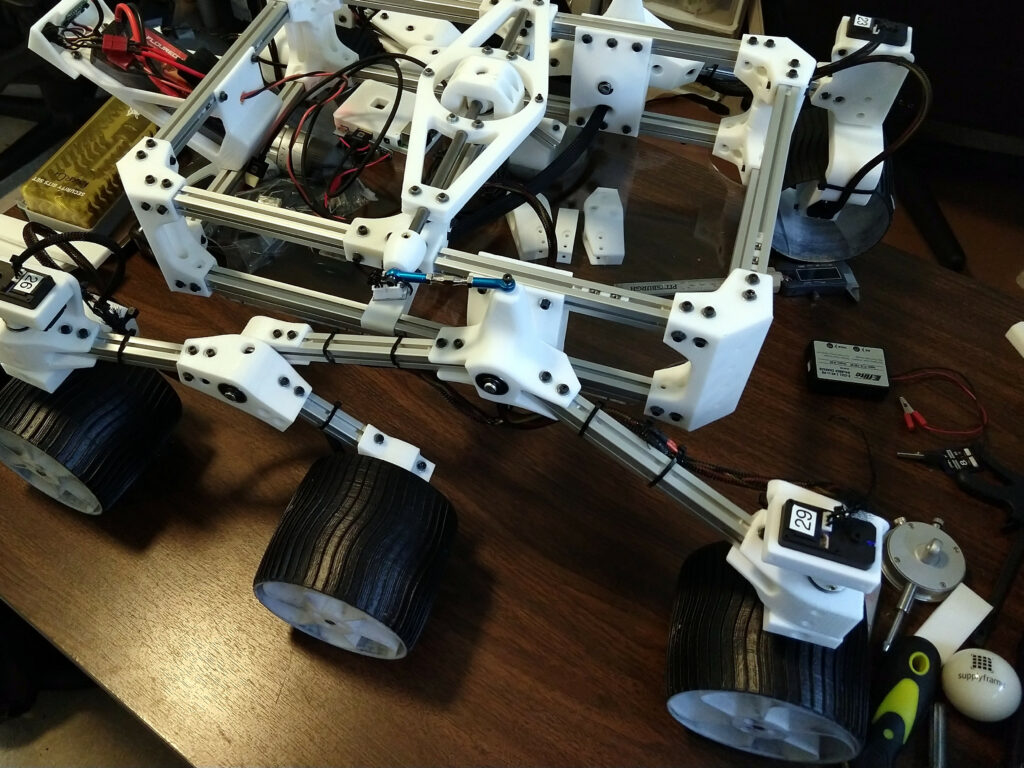

Aluminum extrusion technology is the process of creating a high-quality rigid frame that can support the weight of a 3D printer. It uses aluminum profiles that are lightweight, sturdy and durable, and can be easily assembled, making it a cost-effective option for 3D printing enthusiasts.

Why Use Aluminum Extrusion Technology?

There are numerous benefits to using aluminum extrusion technology in 3D printing. Firstly, it allows for greater stability and accuracy in printing, as the frame is less likely to warp or bend under high temperatures. It also enables easy modifications and upgrades to the 3D printer with no need for additional welding or fabrication.

Comparing Aluminum Extrusion versus Wooden Frames

Using aluminum extrusion technology offers several advantages over traditional wooden frames. Firstly, aluminum frames are sturdier and more durable, providing greater stability during printing. They are also easier to assemble and disassemble, making upgrades and maintenance simple. Wooden frames, on the other hand, can easily warp and deteriorate over time, leading to inaccurate printing and requiring frequent replacements.

| Aluminum Extrusion | Wooden Frame | |

|---|---|---|

| Stability | Highly Stable | Vulnerable to Warping |

| Durability | Long-lasting | Short Lifespan |

| Assembly | Easy to Assemble/Disassemble | Difficult to Install/Uninstall |

| Customization | Simple Modifications/Upgrades | Complex Alterations Required |

Comparing Aluminum Extrusion versus Welded Frames

Another alternative to an aluminum extrusion frame is a welded metal frame. Although welded frames may seem like a sturdy option, they can be costly, difficult to customize and upgrade, and prone to warping due to heat exposure during the 3D printing process. Furthermore, the welding process can weaken the overall structure of the frame.

| Aluminum Extrusion | Welded Frame | |

|---|---|---|

| Stability | Highly Stable | Vulnerable to Warping |

| Durability | Long-lasting | Susceptible to Heat Damage |

| Assembly | Easy to Assemble/Disassemble | Difficult to Install/Uninstall |

| Customization | Simple Modifications/Upgrades | Complex Alterations Required |

| Cost | Affordable | Expensive |

Conclusion

There’s no denying that using aluminum extrusion technology is a game-changer in the world of 3D printing. It provides greater stability and accuracy during printing, enables easy customization, is affordable and durable. It’s a great option for anyone looking for an effective and efficient way to upgrade their 3D printing game.

Upgrade Your 3D Printing Game with Aluminum Extrusion Technology

Thank you for taking the time to read our article about upgrading your 3D printing game with aluminum extrusion technology! We hope you found it informative and useful in your future 3D printing endeavors. Now that you know more about the benefits of using aluminum extrusions in your 3D printer, we encourage you to give it a try.

By incorporating aluminum extrusions into your printing setup, you’ll be able to take advantage of its durability, precision, and versatility. The sturdiness of aluminum extrusions will help ensure that your 3D printer remains stable during the printing process, resulting in higher quality prints. Plus, the precision offered by aluminum extrusions will allow for greater accuracy and detail in your prints to bring your designs to life.

Furthermore, aluminum extrusions can offer unparalleled versatility when it comes to customizing your 3D printer to suit your specific needs. With different sizes, shapes, and lengths available, you can create a truly unique printing setup that will enable you to print even the most complex designs with ease.

So, what are you waiting for? Upgrade your 3D printing game with aluminum extrusion technology today and start experiencing the benefits for yourself. We hope you have enjoyed reading this article and learned something new, and we look forward to bringing you more content in the future to help you continue improving your 3D printing skills.

People also ask about Upgrade Your 3D Printing Game with Aluminum Extrusion Technology:

-

What is aluminum extrusion technology?

Aluminum extrusion technology is a process of manufacturing complex shapes and designs by forcing aluminum material through a shaped opening in a die. It is commonly used in the manufacturing of 3D printers for their frames and other structural components.

-

What are the benefits of using aluminum extrusion technology in 3D printing?

- Aluminum extrusion technology provides a sturdy and durable frame for 3D printers, which can result in better print quality and accuracy.

- The modular design of aluminum extrusion technology allows for easy customization and future upgrades to the printer.

- Aluminum extrusion technology is lightweight, making it easier to move and transport the printer if necessary.

- The aluminum material used in extrusion technology has excellent heat dissipation properties, which can help regulate the temperature of the printer and prevent overheating.

-

Can I upgrade my existing 3D printer with aluminum extrusion technology?

Yes, many manufacturers offer aluminum extrusion kits that can be used to upgrade an existing 3D printer. However, it is important to ensure that the kit is compatible with your specific printer model before purchasing.

-

Is aluminum extrusion technology more expensive than other materials?

Aluminum extrusion technology can be more expensive than other materials such as acrylic or wood, but it offers superior durability and customization options. Additionally, the cost of aluminum extrusion technology has decreased in recent years, making it a more affordable option for 3D printing enthusiasts.

-

What should I consider when selecting an aluminum extrusion kit?

- The compatibility of the kit with your existing printer model

- The size and weight of the extrusion pieces compared to the size of your printer

- The overall cost of the kit and any additional tools or materials needed for installation

- The level of customization and flexibility offered by the kit