Printer

Revolutionizing Manufacturing with Alpha’s 3D Printing Technology

Revolutionizing the manufacturing processes is no more a dream, thanks to Alpha’s 3D printing technology. The concept of 3D printing has come a long way since its inception and now it has gained a foothold in almost every industry.

Are you curious about how this technology can transform the way we produce goods? Imagine producing products layer by layer, without any wasted material, unlike traditional methods where we extract raw materials and produce items in bulk. Alpha’s 3D printing technology utilizes this process reducing waste while increasing efficiency in production process.

This futuristic approach to manufacturing offers endless possibilities for the future of production. A product that was once difficult or impossible to manufacture can now be created in a matter of hours. It could significantly change the way we produce goods, as it accelerates the process of designing, prototyping, and production, ultimately leading to a quicker go-to-market time. The technology can benefit both small and large-scale industries and could be the key to unlocking new levels of success for businesses in different sectors.

If you are interested in learning more about Alpha’s 3D printing technology and its impact on the future of manufacturing, this article is a must-read. This innovative technology is set to revolutionize manufacturing as we know it, and you wouldn’t want to miss out on what it could mean for your business.

“Alpha 3d Printing” ~ bbaz

Revolutionizing Manufacturing with Alpha’s 3D Printing Technology

The Basics of 3D Printing

3D printing involves printing three-dimensional objects from digital designs. This is done by layering materials such as plastic or metal on top of each other until the object is complete. This technology has been around for a few decades but has only started to take off in recent years. Alpha has been at the forefront of this revolution and has been developing their own unique 3D printing technology.

Traditional Manufacturing vs 3D Printing

Traditional manufacturing processes often require expensive machinery and take a long time to set up. This means that it can take a long time to produce a single part or product. On the other hand, 3D printing takes less time to set up and produces objects in a fraction of the time it would take using traditional methods. Another advantage of 3D printing is that it allows for the creation of complex shapes that would be difficult or impossible to make using traditional manufacturing methods.

| Traditional Manufacturing | 3D Printing |

|---|---|

| Expensive machinery required | Less expensive machinery required |

| Takes a long time to set up | Quick setup times |

| Production times are long | Produces objects in a fraction of the time |

| Cannot produce complex shapes easily | Can create complex shapes easily |

The Advantages of Alpha’s 3D Printing Technology

Alpha’s 3D printing technology is unique because it uses a combination of plastic and metal to produce parts. This means that it can produce parts that are both strong and lightweight. Furthermore, Alpha’s technology allows for the production of large parts, which is not possible with many other 3D printing technologies. Another advantage of Alpha’s technology is that it can produce parts with high accuracy and precision.

Applications of Alpha’s 3D Printing Technology

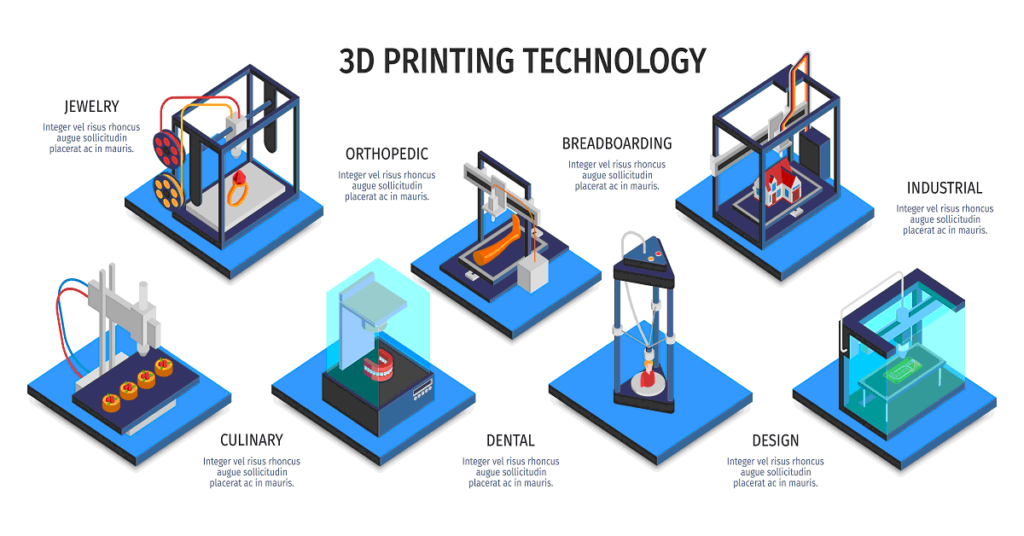

Alpha’s 3D printing technology has a wide range of applications. It can be used in the aerospace industry to produce lightweight and strong components for aircraft. It can also be used in the automotive industry to produce parts that are both strong and durable. In the medical industry, Alpha’s technology can be used to produce prosthetics and other medical devices that are custom-made for patients.

The Future of Manufacturing

Alpha’s 3D printing technology is just one example of how manufacturing is being revolutionized. As technology continues to advance, it is likely that we will see more and more innovative manufacturing techniques emerging. This could lead to faster production times, better quality products, and lower costs.

Final Thoughts

Overall, Alpha’s 3D printing technology is an exciting development in the manufacturing industry. It has the potential to change the way we produce everything from aircraft parts to medical devices. The advantages of 3D printing over traditional manufacturing processes are clear, and Alpha’s technology takes this one step further with its unique combination of plastic and metal materials. As technology continues to advance, we can expect to see even more groundbreaking developments in this field.

Revolutionizing Manufacturing with Alpha’s 3D Printing Technology

As we close this discussion on the potential revolutionizing impact of Alpha’s 3D Printing Technology on manufacturing, we want to thank you for your attention and interest. The vision of a new quality in production, profit and efficiency is closer than ever before.

With 3D printing, manufacturers can create complex geometries with less waste than traditional manufacturing methods. Moreover, they can identify and solve for parts that have been problematic for their products in the past. Further, Alpha’s 3D Printing Technology offers the ability to manufacture orders on-demand, eliminating the need for large stockpiles of finished products.

In conclusion, we believe that Alpha’s 3D Printing Technology could be a game-changer not only for traditional industrial processes but also for small businesses and consumers. The accessibility and affordability of these new devices allow anyone with a great idea to bring it to life quicker than ever before. Thank you for reading and we hope you continue to follow this exciting progress towards revolutionizing manufacturing.

People Also Ask about Revolutionizing Manufacturing with Alpha’s 3D Printing Technology:

- What is 3D printing technology?

- What are the benefits of using 3D printing technology in manufacturing?

- How can Alpha’s 3D printing technology revolutionize manufacturing?

- What industries can benefit from Alpha’s 3D printing technology?

- Is Alpha’s 3D printing technology cost-effective?

3D printing technology is a process of creating three-dimensional objects from a digital file by layering materials until the final product is formed.

The benefits of using 3D printing technology in manufacturing include faster production times, reduced costs, greater design flexibility, and customization options.

Alpha’s 3D printing technology can revolutionize manufacturing by enabling companies to create complex and customized products more efficiently and with higher quality. This can lead to increased productivity, reduced waste, and improved profitability.

Industries that can benefit from Alpha’s 3D printing technology include aerospace, automotive, healthcare, and consumer products.

Yes, Alpha’s 3D printing technology is cost-effective because it reduces the need for expensive tooling and molds, and it allows for faster prototyping and production times.