Printer

Revolutionizing Manufacturing with 3D Printed Inconel Technology

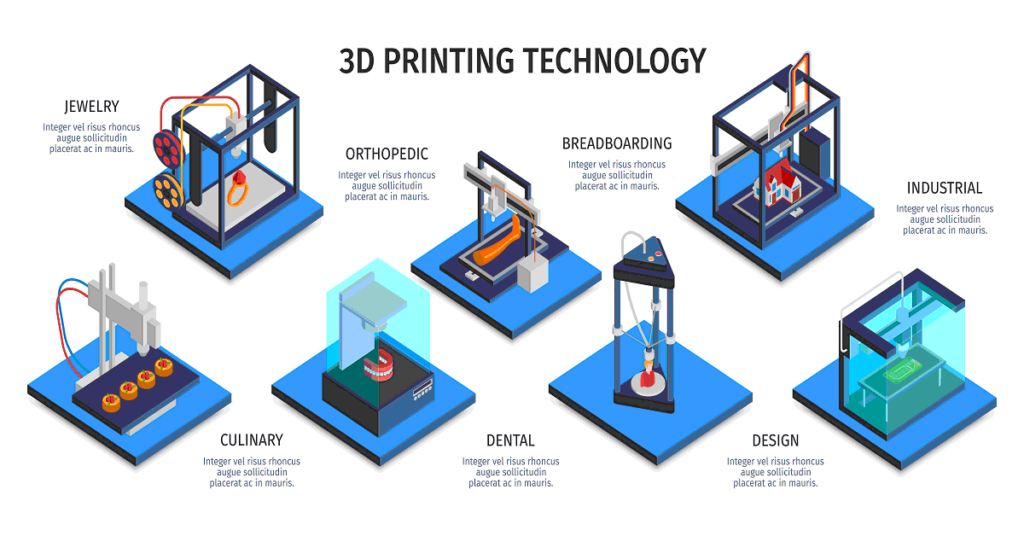

Revolutionizing manufacturing has been the continuous goal of the industry. With the advent of 3D printing, a new frontier in manufacturing has been opened. The use of 3D printing technology has enabled manufacturers to produce parts and components with greater precision and speed than ever before. In fact, the potential of 3D printing to transform the manufacturing industry is only just beginning to be realized.

One area where the benefits of 3D printing are already being felt is in the production of parts made from Inconel. Inconel is a powerful alloy that is known for its ability to withstand extreme temperatures and pressures. These properties make it an ideal material for use in industries such as aerospace and renewable energy. However, the traditional manufacturing processes for Inconel are often difficult and time-consuming, making it unsuitable for mass production.

Enter 3D printing technology. With the use of 3D printing, manufacturers can now produce Inconel parts and components quickly and efficiently. 3D printing enables manufacturers to produce complex geometries that would be impossible to fabricate with traditional machining methods. Furthermore, the precision of 3D printing ensures that each component is precise and consistent, resulting in higher quality parts that perform better and last longer.

Revolutionizing manufacturing with 3D printed Inconel technology is no longer a pipe dream; it’s a reality. If your industry relies on Inconel parts and components, it’s time to consider the benefits of 3D printing. By embracing this cutting-edge technology, you can produce high-quality parts more efficiently and cost-effectively than ever before. Read on to learn more about the incredible possibilities of 3D printing and how it can help take your production processes to the next level.

“3d Printed Inconel” ~ bbaz

Revolutionizing Manufacturing with 3D Printed Inconel Technology

Manufacturing technology has come a long way over the centuries, from handcrafting to mass production methods. However, as we approach the fourth industrial revolution, the focus is on innovation and customization of products while reducing time and costs. This is where 3D printing comes in, and it’s not just for plastic models anymore. The ability to print complex shapes and designs in metal with 3D printing technology has revolutionized manufacturing, especially with the use of inconel. Here’s how.

What Is Inconel?

Inconel is a nickel-chromium-based superalloy known for its high temperature-resistant properties, making it perfect for demanding applications such as gas turbines, chemical plants, and aerospace. The traditional manufacturing process of casting and forging inconel is time-consuming and expensive, and welding it is not an option due to its brittleness at high temperatures. 3D printing solves these challenges while also introducing new possibilities.

Comparing Traditional Manufacturing Methods to 3D Printing Inconel

| Traditional Methods | 3D Printing | |

|---|---|---|

| Time | Takes weeks/months | Takes hours/days |

| Cost | Expensive | Cheaper |

| Complexity | Difficult to produce complex shapes | Perfect for complex designs and shapes |

| Material Waste | Higher | Lower |

| Flexibility | Not easily customizable | Highly customizable |

Time and Cost

Traditional methods such as casting and forging inconel can take weeks, if not months, to produce a single product due to the time needed to create molds or die templates. Additionally, traditional manufacturing methods require numerous setup phases, which increase production costs. In comparison, 3D printing can produce the same parts in a matter of hours or days, depending on their complexity, without the need for costly die templates. This reduces manufacturing times and costs.

Complexity and Customization

Traditional methods often fail when it comes to producing parts with intricate designs because of the lack of flexibility and its limitations in producing complex designs. However, 3D printing eliminates this limitation by accommodating customizations to even the most complicated shapes and designs. Inconel 3D printing technology has opened up new horizons in aerospace, defense, and medical applications by producing parts that would have been considered impossible using traditional methods.

Waste Reduction

3D printing technology significantly reduces wastes as opposed to traditional manufacturing methods that produce a considerable amount of material waste. With 3D printing, wasted materials can often be recycled, allowing for significant cost savings over time. The reduction in waste also makes 3D printing more environmentally friendly than traditional manufacturing methods.

Advantages of Using 3D Printing for Inconel Processes

Inconel 3D printing technology offers several advantages over traditional manufacturing methods when producing inconel parts:

Faster Product Development

2D drawings or CAD files can be used to design parts, which takes little time or money. Additionally, the setup time required for printing an object is minimal, making it possible to produce and prototype parts with higher-speed levels than conventional manufacturing methods.

Improved Technical Properties

With 3D printing technology, processed materials can include additional reinforcement such as fibers, ceramic reinforcements, and nanomaterials that traditional technologies may have difficulty processing. This results in improved technical properties, such as corrosion resistance, durability, wear resistance, and strength.

Greater Customization

With 3D printing technology, companies can customize designs and produce small batches of products. Additionally, inconel 3D printing allows manufacturers to combine various parts to achieve the desired result, so design possibilities are endless.

Conclusion

In conclusion, inconel 3D printing technology has opened up many new possibilities in the manufacturing industry, and it is transforming traditional manufacturing processes. The advantages offered by 3D printing technology are making it possible to explore design concepts that were once considered impossible. Despite the cost of purchasing a 3D printer can be high, it significantly reduces time, cost, waste, and offers flexibility beyond traditional manufacturing methods. With continuous improvement and innovation in 3D printing technology, the future looks bright for manufacturers that adopt this cutting-edge technology.

Thank you for taking the time to explore the possibilities of revolutionizing manufacturing with 3D printed Inconel technology. As you have learned, this technology has the potential to streamline production, reduce costs, and improve product quality. By allowing manufacturers to create designs that were previously impossible using traditional manufacturing methods, 3D printing with Inconel has opened the door to a new era of innovation.

We hope this article has provided valuable insight into the benefits and applications of 3D printing with Inconel. This revolutionary technology is already making waves in industries from aerospace to medical devices, and the future looks bright for further research and development.

As 3D printing technology advances, we can expect even more exciting innovations and opportunities for manufacturers. We invite you to stay up-to-date with the latest trends and developments in 3D printing and to continue exploring the possibilities of using Inconel to enhance your manufacturing processes. Thank you again for your interest in this cutting-edge technology!

People Also Ask About Revolutionizing Manufacturing with 3D Printed Inconel Technology:

- What is 3D printed Inconel technology?

- What are the benefits of using 3D printed Inconel technology?

- How does 3D printed Inconel technology compare to traditional manufacturing methods?

- What industries are benefiting from 3D printed Inconel technology?

- What is the future of 3D printed Inconel technology?

3D printed Inconel technology is the use of additive manufacturing to produce parts made from Inconel, a high-strength, heat-resistant nickel-based alloy. The process involves building up layers of material using a 3D printer until the desired shape is achieved.

The benefits of using 3D printed Inconel technology include faster production times, reduced waste, and the ability to create more complex geometries than traditional manufacturing methods. In addition, Inconel is known for its superior strength and resistance to corrosion and high temperatures, making it ideal for use in aerospace, defense, and other high-performance applications.

Compared to traditional manufacturing methods such as casting or forging, 3D printed Inconel technology offers greater design flexibility, faster turnaround times, and lower costs for small-batch production runs. However, it may not be as cost-effective for high-volume production due to the higher cost of materials and longer print times.

Industries that are benefiting from 3D printed Inconel technology include aerospace, defense, oil and gas, and automotive. These industries require high-strength, heat-resistant materials and often have complex geometries that can be difficult to produce using traditional manufacturing methods.

The future of 3D printed Inconel technology looks bright, with continued advancements in materials and printing technology. As the cost of 3D printers continues to decrease, it is expected that more industries will adopt this technology for their manufacturing needs.