Printer

Revolutionize Your Races with High-Quality 3D Printed Tracks

Racing enthusiasts are always on the lookout for new and exciting ways to enhance their experience. If you are one of them, then you’re in luck! Imagine revolutionizing your races with high-quality 3D printed tracks. This is not only possible but could be a game-changer for your racing events.

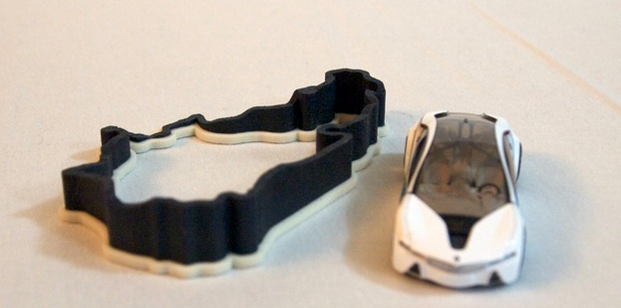

Thanks to the recent advancements in technology, 3D printing has become more accessible and affordable than ever. With 3D printing, it’s now possible to create any track design you can think of with incredible precision and detail. The days of using generic, standard tracks are long gone.

But what does this mean for racers? Imagine having the ability to create custom tracks that are completely unique to your event. The flexibility of 3D printing allows for endless possibilities. Not to mention, the durability of the material used ensures that these tracks will last for years to come.

If this sounds too good to be true, we assure you it’s not. With 3D printed tracks, the sky’s the limit. Whether it’s for competitive racing or simply for hobbyists looking to spice up their races, 3D printing allows for maximum creativity and customization. So why settle for anything less? Revolutionize your races today with high-quality 3D printed tracks.

“3d Printed Tracks” ~ bbaz

Revolutionize Your Races with High-Quality 3D Printed Tracks

Introduction

Racing enthusiasts always strive to make their races more exciting and challenging. The introduction of high-quality 3D printed tracks has revolutionized this aspect of racing. These tracks, made with precision and accuracy, offer great advantages over traditional tracks. This article explores the benefits, cost-effectiveness, and quality of 3D printed tracks compared to traditional methods.

Quality

The quality of 3D printed tracks surpasses that of traditional tracks. With highly detailed designs and accurate measurements, the 3D printed tracks offer a superior degree of precision. 3D printing technology also leaves no room for human error, which often occurs during manual track making. With 3D printed tracks, racers get to enjoy faster speeds and smoother rides.

Cost-effectiveness

Producing conventional tracks can be expensive due to the associated costs, like excavation and manual labor. 3D printing offers a cost-effective solution for creating racing tracks. With 3D printing, materials are used efficiently, and minimal waste is produced. Additionally, the time required to create 3D printed tracks is significantly shorter than for traditional tracks, making it a more cost-effective solution overall.

Customization

3D printing technology allows for high levels of customization in creating race tracks. Racetracks can be designed to suit any criteria and tailored to different requirements, like track conditions, weather patterns, and topography. The flexibility offered by this approach means that racing enthusiasts can enjoy greater variety and personalization.

Eco-friendliness

The 3D printing process produces little to no waste, making it an eco-friendlier option for creating racetracks. Traditional methods of building racetracks involve excavation and dispose of excess materials, which can harm the environment. 3D printing ensures minimal waste and conserves natural resources.

Durability

Durability is a pivotal factor when it comes to racetracks. 3D printed tracks are renowned for their high durability compared to traditional tracks since they are made with sturdy materials like nylon and polycarbonate. These materials can withstand harsh environments and repetitive use, making them a long-lasting solution.

Maintenance

Maintaining traditional tracks can be challenging, particularly outdoor racetracks that are at the mercy of weather elements. 3D printed tracks offer an easy-to-maintain solution since they are resistant to wear and tear and require minimal upkeep. Any damages can be quickly repaired with 3D printing technology.

Table Comparison

| Features | Conventional Tracks | 3D Printed Tracks |

|---|---|---|

| Quality | Less Detailed and Lower Precision | Higher Detailed and More Precise |

| Cost-effectiveness | Expensive due to manual labor and excavation costs | Less expensive due to efficient material use and shorter production time |

| Customization | Limited customization options | Highly customizable based on specific needs |

| Eco-friendliness | More waste produced and harmful to the environment | Limited waste and conserves natural resources |

| Durability | Lower durability requiring frequent maintenance | Higher durability requiring less maintenance |

Opinion

In conclusion, 3D printed tracks offer many advantages over traditional racetracks. They are more detailed, precise, and cost-efficient while also providing greater flexibility, eco-friendliness, and durability. While it is still a relatively new technology, 3D printing has revolutionized the way racing tracks are created, offering racing enthusiasts and enthusiasts alike an exciting and enjoyable experience.

Revolutionize Your Races with High-Quality 3D Printed Tracks

Dear readers,

We hope that after reading our latest article, you are as excited as we are about the possibilities of revolutionizing your races with high-quality 3D printed tracks. As you have learned, 3D printing technology has opened up an entirely new world of possibilities for designing and customizing race tracks. With the ability to create any shape or size, the possibilities truly are endless.

Whether you are a hobbyist looking for a new challenge, a coach seeking innovative training tools, or an event organizer wanting to wow your audience, 3D printed race tracks are the way of the future. Not only do they offer unparalleled flexibility in terms of design, but they also provide a more cost-effective and environmentally friendly alternative to traditional manufacturing methods.

So, what are you waiting for? Whether you’re looking to build a custom track in your own backyard, or planning a large-scale event, we encourage you to explore the possibilities of 3D printing. The benefits are undeniable, and the potential for creativity is limited only by your imagination. Thank you for taking the time to read our article, and we hope to see you soon on the race track of the future.

Revolutionize Your Races with High-Quality 3D Printed Tracks

People Also Ask:

- What are the benefits of using 3D printed tracks for racing?

- 3D printed tracks offer superior accuracy and precision, allowing for more realistic and challenging races.

- They are customizable, so you can create unique tracks that suit your specific needs and preferences.

- They are durable and long-lasting, ensuring that your investment in a 3D printed track will pay off over time.

- How do 3D printed tracks compare to traditional tracks?

- 3D printed tracks offer greater flexibility and freedom in terms of design, while traditional tracks are often limited in their shapes and dimensions.

- 3D printed tracks are also more precise and accurate, resulting in more consistent and fair races.

- Additionally, 3D printed tracks can be constructed more quickly and efficiently than traditional tracks, making them a more cost-effective option in many cases.

- Can 3D printed tracks be used for both indoor and outdoor racing?

- Yes, 3D printed tracks can be designed and constructed for both indoor and outdoor use, depending on your specific needs and preferences.

- However, it is important to select materials that are appropriate for the environment in which the track will be used.

- For example, if the track will be used outdoors, it may need to be constructed from materials that are weather-resistant and UV-stable.

- Are there any limitations to using 3D printed tracks for racing?

- While 3D printed tracks offer many benefits, there are some limitations to consider.

- For example, the materials used to construct the track may affect its durability and longevity, so it is important to select high-quality materials that will stand up to frequent use.

- Additionally, the cost of 3D printing technology may be prohibitive for some individuals or organizations.

- Where can I find high-quality 3D printed tracks for my racing needs?

- There are many companies and individuals that specialize in 3D printing custom tracks for racing, so it is important to do your research and select a reputable provider.

- Look for a provider that has experience working with your specific type of racing, whether it is slot cars, radio-controlled cars, or another type of vehicle.

- You should also ask for references and examples of previous work to ensure that the provider can deliver the quality and customization you need.