Printer

Revolutionize Your Printing Needs With 3D Printer Affirm

Are you tired of the limitations and high costs of traditional printing methods? Look no further than the 3D Printer Affirm! This revolutionary technology has completely transformed the world of printing, giving individuals and businesses alike unprecedented flexibility and creative freedom.

With its cutting-edge design software and state-of-the-art printing technology, the 3D Printer Affirm allows users to fully customize each and every detail of their products. Need to create a unique prototype for a new invention? No problem! Want to print intricate and complex structures that would be impossible with traditional methods? The 3D Printer Affirm has got you covered.

Don’t settle for mediocre print quality and limited options. Revolutionize your printing needs and unlock a whole new world of possibilities with the 3D Printer Affirm. So why hesitate? Purchase your very own today and experience the future of printing technology!

“3d Printer Affirm” ~ bbaz

Revolutionize Your Printing Needs With 3D Printer Affirm

Introduction

Printing has been revolutionized with the latest trend, 3D printing. This emerging technology offers an ideal solution to transform complex digital designs into real physical models. It offers a new way to create prototypes, experiment with, and execute conventional manufacturing techniques. This blog post offers an insightful look at 3D printers, their benefits, and how they can help revolutionize your printing needs.

What is a 3D Printer

A 3D printer is a machine that uses three-dimensional printing techniques to create tangible objects from digital designs. It prints layer by layer until the desired shape is obtained; it is an additive process. The printer materials used in 3D printing are PLA or ABS plastic, resins, or metals.

The Working of the 3D Printer

3D printing starts with a 3D modeling design done using computer-aided design (CAD) software. The design file is then exported as an STL file, which is read by the 3D printer software. The 3D printer software slices the design file into layers and provides commands for the printer head to follow. Then, the printer melts the material, places it on a bed, and from there, it builds the object layer by layer in accordance with the printed instructions.

Benefits of 3D Printing

Precision

The precision provided by a 3D printer is unmatched; it can print objects with intricate details that traditional manufacturing cannot. Objects can be printed with resolution and accuracy that reaches a hundredth of a millimeter with prints that are literally as good as gold. This unparalleled precision is crucial when designing complex parts, especially in printing engineering prototypes or detailed models.

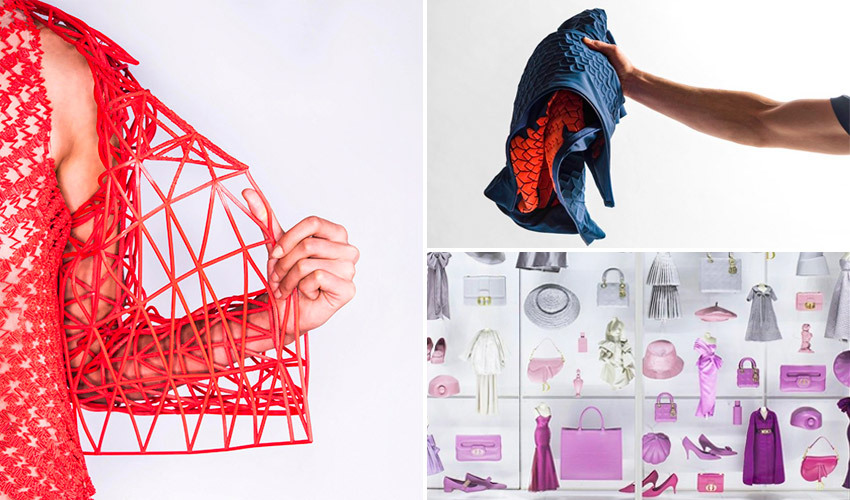

Customized Production

Customized production has never been this efficient. 3D printers offer designers and manufacturers the ability to create tailor-made products with maximum individualization. The custom design produced by a 3D printer ensures that each product is unique and personalized to fit consumers’ specific needs. This is an excellent opportunity to differentiate your business offerings from competitors while providing a better customer experience.

Fast Turnaround Time

3D printers provide quick turnaround time, unlike the traditional manufacturing method with long lead times. For example, the casting process can take up to several weeks to complete; 3D printers can produce the same model within a few hours, depending on the complexity of the design. It allows creative freedom, quicker reaction times to changes, and accelerated product development, which is beneficial for businesses producing specialized products.

3D Printing Will Revolutionize the Manufacturing Industry

3D printing technology is changing the future of manufacturing. It has broad capabilities, which include creating customized products, producing affordable high-quality parts, and supporting rapid prototyping that traditional manufacturing cannot provide. The integration of 3D printing with other industry technologies such as AI and IoT will accelerate its adoption rate in applications like surgical studies or shortening the supply chain.

3D Printer Affirm

Top Features of 3D Printer Affirm

3D Printer Affirm offers an array of features that make it stand out from the crowd. Its software can easily be integrated with SolidWorks and Catia models, and it prints using the latest Fused Deposition Modeling (FDM) technology.

Performance

3D Printer Affirm has excellent resolution quality, and its output is of professional grade. Its features have made it suitable for industries that demand precise and accurate manufacturing. Given that its performance is user-friendly, it is suitable for both beginners and professionals in the industry.

Affordable

The initial cost of acquiring 3D Printer Affirm is comparatively lower than the traditional industrial machines. It designed with an open architecture, which enables different options to print materials affordably.

Comparison Table of 3D Printers

| Features<\th> | 3D Printer Affirm<\th> | Makerbot Replicator Z18<\th> | Ultimaker S5 |

|---|---|---|---|

| Printing Technology<\td> | Fused Deposition Modeling (FDM) Technology<\td> | MakerBot PLA Filament<\td> | FDM Technology<\td> |

| Layer Resolution <\td> | 100 microns<\td> | 100 microns<\td> | 20 microns<\td> |

| Printing Volume<\td> | the print volume up to 8x8x8 inches.<\td> | the print volume of 706 cubic inches.<\td> | 330 x 240 x 300mm (13 x 9.4 x 11.8in) build volume<\td> |

| Price<\td> | $32,000 – $36,000<\td> | $6,499<\td> | $5,995<\td> |

Conclusion

The emerging trend of 3D printing technology has revolutionized manufacturing across industries, providing new ways to create prototypes, experiment with, and execute traditional manufacturing techniques. By using the latest Fused Deposition Modeling (FDM) Technology, 3D Printer Affirm provides unmatched features to produce accurate, precise, and customizable prints at an affordable price. All these benefits have made 3D printing the future of manufacturing.

Thank you for taking the time to read about the revolutionizing technology of 3D printing. I hope this article has provided you with insightful information on how 3D printing can transform and streamline your printing needs.

By incorporating 3D printing into your business or personal projects, you will have the ability to create prototypes, models and customized objects in a way that traditional printing methods cannot match. Not only does this technology offer a level of precision, but also the option to print in various materials from plastics to metals and even food.

So take the leap into the exciting world of 3D printing and watch as it transforms the way you turn creative ideas into tangible objects. Don’t forget to check out Affirm, your go-to provider for flexible financing options, making it easier than ever to add a 3D printer to your arsenal.

People also ask about Revolutionize Your Printing Needs With 3D Printer Affirm:

-

What is a 3D printer and how does it work?

A 3D printer is a machine that creates three-dimensional objects from a digital file. It works by layering material, such as plastic or metal, on top of each other to create the final product.

-

What are the benefits of using a 3D printer for printing needs?

There are several benefits of using a 3D printer for your printing needs. These include faster production times, lower costs, and the ability to create complex shapes and designs that would be impossible with traditional printing methods.

-

What kind of materials can be used with a 3D printer?

3D printers can use a variety of materials, including plastics, metals, ceramics, and even food. The type of material used will depend on the specific printer and the requirements of the project.

-

Can 3D printers be used for large-scale production?

While 3D printers are not typically used for large-scale production at this time, they do have the potential to be used in this way in the future. As technology continues to improve, 3D printers may become a more common tool for manufacturing and production.

-

What industries are currently using 3D printing technology?

3D printing technology is being used in a variety of industries, including healthcare, aerospace, automotive, and architecture. It is also being used by artists, designers, and hobbyists for personal projects.