Printer

Revolutionize Your Printing Experience with Triple Extruder 3D Printer

A revolution in 3D printing technology has arrived and it is called the Triple Extruder 3D Printer. With this latest innovation, you can now achieve more intricate designs with a higher level of detail than ever before. This printer is truly a game-changer as it brings a new level of flexibility and efficiency to the industry.

Imagine being able to print three different colors or materials at the same time. The Triple Extruder 3D Printer makes it possible to print detailed models, functional prototypes, and even production parts in a fraction of the time that it would take to print each object individually.

If you want to revolutionize your printing experience, then the Triple Extruder 3D Printer is the way to go. It provides unparalleled versatility and convenience for your design projects, whether you are a hobbyist or an industrial designer. You will have endless possibilities at your fingertips with this innovative printer.

In conclusion, the Triple Extruder 3D Printer is a powerful tool that will change the way you work with 3D printing technology. You will be amazed by the level of detail and complexity that you can achieve in your designs, and the speed at which you can produce them. So, why wait? Get your Triple Extruder 3D Printer today and start taking your creative projects to the next level!

“Triple Extruder 3d Printer” ~ bbaz

The Rise of 3D Printing Technology

The world is slowly embracing the era of three-dimensional printing technology. People are now turning to 3D printers as their go-to solution for different industrial and commercial applications. With the continuous evolution of technology, it’s no surprise that the innovative thinkers and industrious doers in the 3D printing industry have come up with a triple extruder 3D printer. Let’s take a closer look at how this printer could revolutionize your printing experience.

Overview of Triple Extruder 3D Printers

Brief History of 3D Printing

Since the invention of the first 3D printer in the 1980s, many other printer designs have evolved. The initial models used a single extruder to build up layer upon layer of the material. These printers produced simple shapes and structures, which were perfect for hobbyists and prototypes. Technological advancements have resulted in the development of triple extruder 3D printers, which enable much more complex 3D printing tasks.

What Is a Triple Extruder 3D Printer?

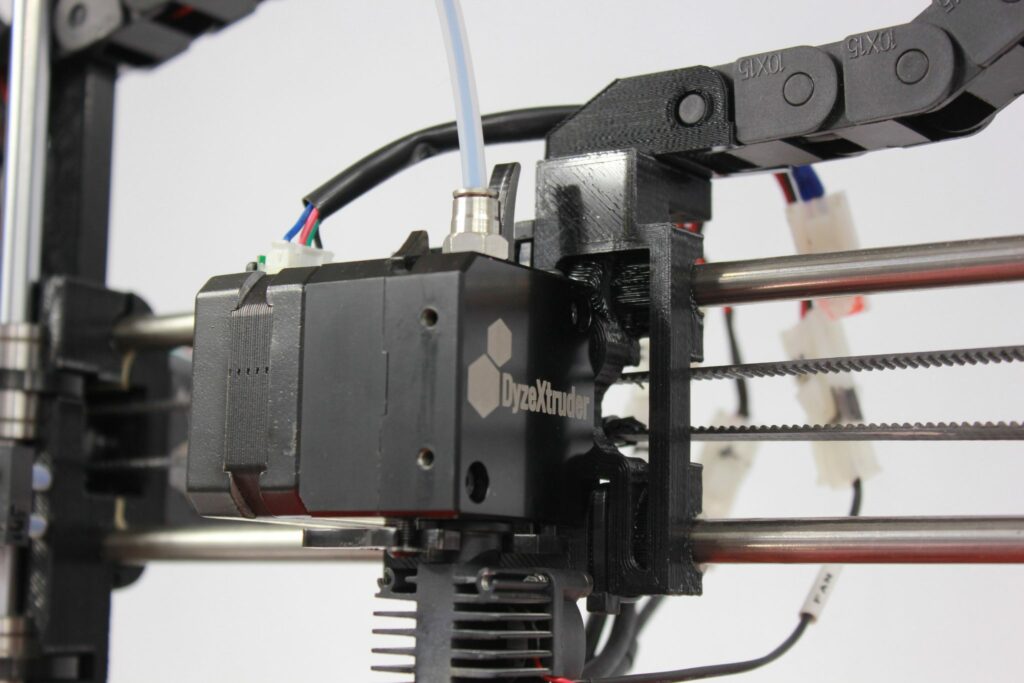

A triple extruder 3D printer is a machine that prints three different materials simultaneously. Unlike the traditional 3D printer that uses one filament spool, the triple extruder uses three spools for printing. The user can program it to print different colours or switch from one type of material to another during printing. This printer has proven to be a game-changer, providing more creative options for designers and manufacturers.

What Can You Do with a Triple Extruder 3D Printer?

Multi-Color Printing Capability

The possibility of using three different coloured filaments in one design provides users with the ability to create colorful and aesthetically pleasing objects that are hard or impossible to obtain using traditional methods.

Functional Designs

The machine’s capability to print with multiple materials simultaneously also allows the creation of complex and functional designs. The combination of tough, high-temperature-resistant, flexible, and transparent materials improves the mechanical properties that make 3D printed products useable in more demanding applications.

Diversification of 3D Printing Applications

The triple extruder 3D printer can use dissolvable filament for multi-material printing, which dissolves when exposed to water, chemicals or heat. This makes it possible for designers to create structures unattainable using traditional methods. Dissolvable material supports intricate overhangs and cavities without the need for support material removal after printing. The technology also enables the printing of conductive 3D objects like antenna and sensors, adding diversity to 3D printing applications.

Triple Extruder 3D Printer vs. Traditional 3D Printers

Printing Speed

The triple extruder 3D printer prints at a rate slower than a traditional 3D printer, mainly due to the multiple materials and colours it uses when printing. However, the convenience of printing multi-colored objects without having to switch between filaments or using a single nozzle to mix colors makes it a more efficient printer overall.

Printing Cost

The cost of operating a triple extruder 3D printer is higher than that of a traditional 3D printer because of the additional costs involved in purchasing and maintaining three extruder heads rather than just one.

Technical skill Requirements

Using a traditional 3D printer doesn’t require too much technical knowledge to operate compared to the triple extruder 3D printer. Triple extruder 3D printer’s complex nature requires advanced knowledge and experience to maximize its potential fully.

Futuristic Potential

Customization

The machine’s ability to print with multiple filaments/materials opens up unlimited possibilities for customization. The sky is the limit when it comes to creating bespoke or personalized products regardless of the form or intended use, whether in the medical, architectural, clothing, automotive or aerospace industries.

Medical Applications

3D printing in medicine has already revolutionized treatment through prosthetics, implants, drug delivery systems, and tissue engineering. Triple extruder 3D printers will take medical 3D printing capabilities to new heights, providing personalized implant solutions that integrate functionality and aesthetics.

Conclusion

The revolution brought in by triple extruder 3D printers cannot be overstated. By providing more options for producers and designers alike, it has sparked a renewal in the way we create and manufacture objects. Although higher on cost and technical requirements, the ability to print multiple materials and colours combined with limitless customization capabilities makes it a worthy investment.

| Criteria | Triple Extruder 3D Printer | Traditional 3D Printer |

|---|---|---|

| Printing Cost | Higher | Lower |

| Printing Speed | Slower | Faster |

| Printing Capabilities (Colors/Materials) | Better | Standard |

| Technical Skill Requirements | High | Low |

Thank you for reading this article on Triple Extruder 3D Printer. We hope you have gained insights into how this printer revolutionizes your printing experience. As technology advances and innovations are being made, having a triple extruder 3D printer at your disposal gives you the advantage of creating more intricate and complex designs with less time.

Having a triple extruder 3D printer means that you can print three different filaments simultaneously or three copies of the same filament at once. This feature not only saves time but also minimizes the need to change filaments during printing, which translates to better quality prints. It also opens up new possibilities when it comes to printing models with multiple colors or materials.

We encourage you to try out the triple extruder 3D printer and discover for yourself the benefits it brings to your printing experience. With its versatile design and superior capabilities, you are sure to produce high-quality prints that will surpass your expectations. Thank you once again for reading and we wish you good luck exploring the world of 3D printing.

People Also Ask about Revolutionize Your Printing Experience with Triple Extruder 3D Printer:

- What is a triple extruder 3D printer?

- What are the benefits of using a triple extruder 3D printer?

- Ability to print with three different materials or colors simultaneously

- Increased efficiency and productivity

- More complex designs and structures can be created

- Cost savings by reducing the need for multiple printers

- What types of projects are best suited for a triple extruder 3D printer?

- Are there any downsides to using a triple extruder 3D printer?

- What should I look for when purchasing a triple extruder 3D printer?

- Reliability and durability of the printer

- Compatibility with different materials and filaments

- User-friendly software and interface

- Price and value for money

- Positive reviews from other users and experts

A triple extruder 3D printer is a type of 3D printer that has three extruders instead of one or two. This allows the printer to print with three different materials or colors at the same time.

A triple extruder 3D printer is ideal for projects that require multiple colors or materials, such as creating prototypes, models, and figurines. It is also useful for printing parts that require support structures, as the third extruder can be used to print the support material.

One potential downside is the increased complexity of the printer, which can lead to more maintenance and upkeep. Additionally, triple extruder 3D printers can be more expensive than single or dual extruder printers. Finally, there may be a learning curve when it comes to designing files for a triple extruder printer, as it requires additional considerations when it comes to color and material selection.