Printer

Revolutionize Your Manufacturing with 3D Printed Lead Screws

Are you looking for a new way to streamline your manufacturing processes? Look no further than 3D printed lead screws. This innovative technology has the potential to revolutionize the way you produce goods and scale your business.

One of the key benefits of 3D printed lead screws is their customization. Instead of relying on off-the-shelf screws that may not fit your exact needs, you can design and print lead screws that are perfectly tailored to your manufacturing process. This level of precision can translate to higher quality products and more efficient production cycles.

Another advantage of 3D printed lead screws is their durability. Made from high-quality materials like stainless steel or titanium, these screws can withstand wear and tear over time. Plus, the printing process itself can result in a stronger overall product design.

If you’re ready to take your manufacturing to the next level, consider implementing 3D printed lead screws into your process. With their customization, durability, and potential cost savings, this technology can help your business thrive in a competitive market. Read on to learn more about how 3D printed lead screws can benefit your operations.

“3d Printed Lead Screw” ~ bbaz

Introduction

Manufacturing has come a long way since the days of mass-production assembly lines and human-operated machines. With the introduction of 3D printing, manufacturing has been revolutionized in unexpected ways. 3D printing allows manufacturers to produce parts with greater precision and speed than traditional methods. One advancement in particular has been with 3D printed lead screws.

What are lead screws?

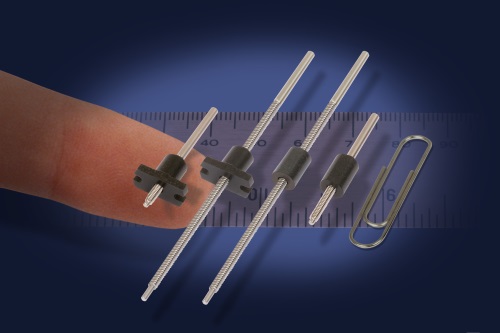

Lead screws are critical components in many mechanical systems. A lead screw is a component that resembles a screw, but with a continuous helical ridge or thread wrapping around a cylinder. The primary function of a lead screw is to convert rotational motion into linear motion.

Traditional manufacturing of lead screws versus 3D printing

Until recently, lead screws have been manufactured using traditional methods such as turning, milling or grinding. These methods had limitations including longer production times, lower precision, and greater complexity. On the other hand, 3D printed lead screws were introduced as a faster, more precise method.

| Traditional manufacturing | 3D printing |

|---|---|

| Longer production times | Faster production times |

| Lower precision | Higher precision |

| Greater complexity | Simplified process |

Advantages of 3D printed lead screws

There are several advantages to using 3D printed lead screws such as:

Customizability

3D printing allows manufacturers to quickly and easily design parts to custom specifications. This means that lead screws can be tailored to specific applications, providing greater flexibility and improved performance.

Cost-effective

3D printing has the potential to decrease the cost of manufacturing lead screws by reducing the amount of machinery required and streamlining the manufacturing process.

Improved speed of production

3D printing enables faster production compared to traditional methods. This is due to the ability to print complex parts in a single piece, without the need for assembly, which saves time and improves efficiency.

Limitations of 3D printed lead screws

While 3D printed lead screws offer several advantages, it is important to note their limitations:

Strength and Durability

3D printed parts are typically less durable and strong than those made using traditional methods. This may not be a problem in some applications, but it could be an issue in high-stress environments.

Surface finish quality

3D printing can produce uneven surface finishes, which can lead to problems in some applications. This limitation can be overcome by post-processing techniques, but this will add cost and time to the production cycle.

Conclusion

3D printing of lead screws has brought a new level of innovation to modern manufacturing. While it has its limitations, this technology provides a cost-effective and customizable way to improve the speed, flexibility, and accuracy of product development across various industries. It is quickly becoming a leading contender in the manufacturing industry, and as the process continues to evolve, the possibilities are endless.

Thank you for taking the time to read our article on revolutionizing your manufacturing process with 3D printed lead screws. We hope that you found our insights informative and helpful.

As you can see, 3D printing technology has opened up new possibilities in the manufacturing industry, and 3D printed lead screws are just one example of how it can improve processes and save time and money. By utilizing 3D printing, manufacturing companies can create high-quality, customized parts at a fraction of the cost of traditional manufacturing methods.

So, whether you are looking to streamline your production process or simply want to explore the latest advancements in the industry, we encourage you to consider 3D printed lead screws as an excellent solution. Thank you again for visiting our blog, and we wish you success in all of your future manufacturing endeavors.

People Also Ask about Revolutionize Your Manufacturing with 3D Printed Lead Screws:

-

What are lead screws?

Lead screws are mechanical components used to convert rotary motion into linear motion. They consist of a threaded rod and a nut, which when turned, move along the length of the rod.

-

What is 3D printing?

3D printing is a process of creating three-dimensional objects by depositing material layer by layer based on a digital model.

-

How can 3D printed lead screws revolutionize manufacturing?

3D printing allows for the creation of bespoke lead screws that are tailored to specific applications. This allows manufacturers to create lead screws that are more efficient, durable, and cost-effective than traditional manufacturing methods.

-

What materials can be used to 3D print lead screws?

Materials such as nylon, polycarbonate, and ABS can be used to 3D print lead screws. These materials offer high strength, durability, and resistance to wear and tear.

-

Are 3D printed lead screws as strong as traditionally manufactured lead screws?

Yes, 3D printed lead screws can be as strong, if not stronger, than traditionally manufactured lead screws. This is because 3D printing allows for the creation of parts with complex geometries and internal structures that cannot be achieved using traditional manufacturing methods.