Printer

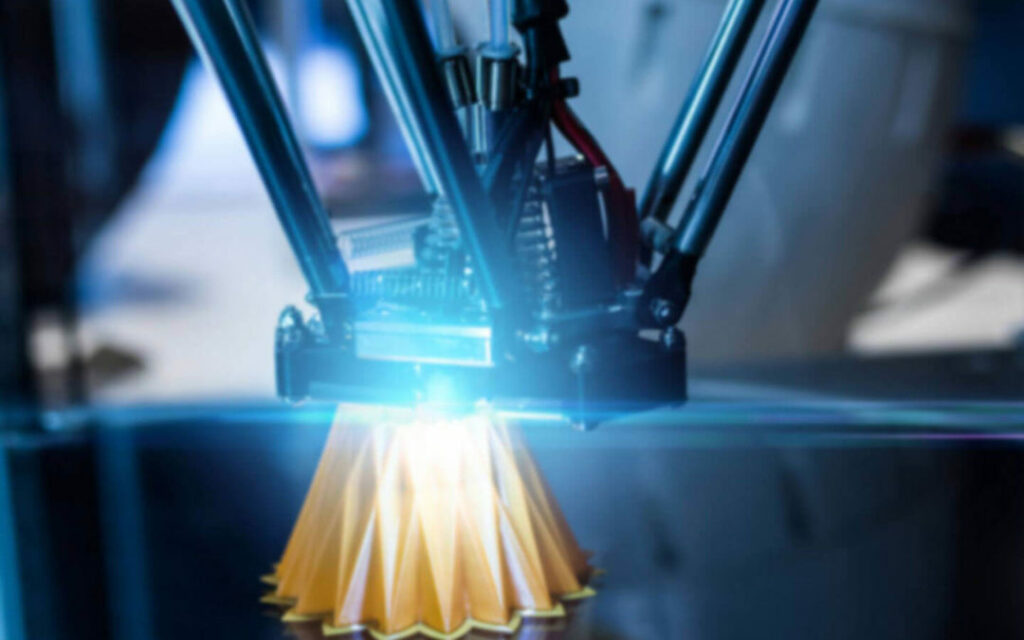

Revolutionize Manufacturing with 3D Printing Inconel Technology

Revolutionizing the manufacturing industry has been the dream of many businesses for years. The introduction of 3D printing technology using Inconel may just be the solution that will finally make this dream a reality. Imagine being able to print complex parts and components at a fraction of the cost and time it would take to produce them using traditional methods. It is no wonder that many businesses are now investing in this technology.

But what makes Inconel technology stand out from the rest? Simply put, Inconel is a superalloy that is known for its excellent strength and durability. It can withstand high temperatures, corrosive environments, and extreme pressure. These properties make it an ideal material for use in a variety of industries, including aerospace, defense, and energy to name a few.

With Inconel 3D printing technology, manufacturers can create highly complex parts and components with precision and speed. The ability to print intricate designs without the need for expensive tooling or molds can help businesses reduce production costs significantly. This technology also allows for on-demand production, which means that businesses can quickly respond to customer demands, ultimately leading to increased profitability.

In conclusion, 3D printing using Inconel technology has the potential to revolutionize the manufacturing industry. The benefits of this technology are evident, and there is no doubt that it will continue to grow in popularity. For businesses that are looking to stay competitive in today’s market, investing in Inconel technology is a wise move. Its ability to produce high-quality, complex designs in a cost-efficient and timely manner is simply unmatched. So, what are you waiting for, explore the world of 3D printing with Inconel today!

“3d Printing Inconel” ~ bbaz

Revolutionize Manufacturing with 3D Printing Inconel Technology

Introduction

3D printing technology has seen significant growth in the recent past, and it’s on its way to revolutionizing manufacturing processes. With the emergence of different materials for 3D printing, it’s now possible to manufacture complex parts with much ease. One such material is Inconel, whose unique properties make it ideal for industries with high-temperature and corrosive environments.

What is Inconel?

Traditional Manufacturing vs. 3D Printing with Inconel

| Traditional Manufacturing | 3D Printing with Inconel | |

|---|---|---|

| Design Flexibility | Low | High |

| Speed of Production | High | Low |

| Cost | High | Low |

| Material Waste | High | Low |

Design Flexibility

Speed of Production

Cost

Material Waste

Advantages of 3D Printing with Inconel

– Complex shapes can be produced with ease.- Less material waste compared to traditional manufacturing.- Highly customized products are possible.- The final product has excellent resistance to heat, corrosion, and pressure.

Disadvantages of 3D Printing with Inconel

– Slow rate of production compared to traditional manufacturing.- Unsuitable for mass production due to time and cost limitations.- May not be as cost-effective as the traditional manufacturing method.

Conclusion

3D printing with Inconel is an excellent technology for industries with high-temperature and corrosive environments. The technology allows the creation of complex shapes with ease, reduced material waste, and highly customized products. However, it’s not ideal for mass production due to time and cost limitations. As the technology keeps improving, it will undoubtedly have a more significant impact on manufacturing in the future.

Thank you for taking the time to read about how 3D printing with inconel technology is revolutionizing manufacturing. We hope this article has been both informative and engaging, and has provided insight into the potential of 3D printing. As we move forward, we anticipate innovative uses of inconel and other materials in 3D printing technologies.

Manufacturing with 3D printing has limitless possibilities, from design freedom to quick iterations and an overall reduction in production time. The benefits of inconel material make it a standout choice for aerospace, automotive, and industrial applications. We can expect to see increased use of inconel in 3D printing as technology continues to improve.

Again, thank you for visiting our blog, and we hope you have gained some valuable knowledge on the vast potential of 3D printing with inconel technology. Be sure to stay tuned for future updates and advancements in the field of manufacturing and 3D printing.

Revolutionizing manufacturing with 3D printing Inconel technology has become a hot topic in the world of engineering and manufacturing. Here are some frequently asked questions and their answers:

-

What is 3D printing Inconel technology?

3D printing Inconel technology is a process that uses 3D printers to produce parts made of Inconel, a high-temperature nickel alloy that is known for its exceptional strength and resistance to heat and corrosion.

-

What are the benefits of using 3D printing Inconel technology?

The benefits of using 3D printing Inconel technology include reduced costs, faster production times, improved design flexibility, and better part quality. Additionally, Inconel parts produced using 3D printing technology have been shown to be stronger and more durable than those produced using traditional manufacturing methods.

-

What industries can benefit from 3D printing Inconel technology?

Industries that can benefit from 3D printing Inconel technology include aerospace, defense, energy, and automotive. In these industries, parts made of Inconel are often required due to their strength and resistance to extreme temperatures and corrosive environments.

-

What are the limitations of 3D printing Inconel technology?

The main limitations of 3D printing Inconel technology are high production costs and limited availability of Inconel powder. Additionally, the size of the parts that can be produced using 3D printing Inconel technology is currently limited by the size of the 3D printers themselves.

-

How can I get started with 3D printing Inconel technology?

If you are interested in using 3D printing Inconel technology, you can start by researching the various types of 3D printers and Inconel powders that are available. You can also work with a 3D printing service provider that specializes in Inconel parts production to help you get started.