Printer

Optimize Resin Printer Performance with Proper Ventilation Enclosure

Resin printers offer excellent printing quality, but their performance can be optimized even further with proper ventilation enclosures. Without proper ventilation, air trapped in the print chamber can affect the curing of the resin, leading to improper prints and wasted material. This is where a well-designed ventilation enclosure comes into play, creating an environment that promotes optimal resin curing.

But why is it so important to optimize your resin printer’s performance? Firstly, efficient curing ensures that prints are stronger and more durable, capable of withstanding wear and tear. Secondly, optimized performance leads to faster printing times, meaning that you can complete more prints in less time. Lastly, proper ventilation also protects the operator from exposure to fumes, making resin printing safer for everyone involved.

Creating a proper ventilation enclosure need not be difficult, and the benefits of doing so are clear. With a few modifications to your printer’s set-up, you can improve the quality, speed, and safety of your resin prints. Consider implementing a ventilation enclosure today and experience the difference it can make in your resin printing world.

Don’t let poor ventilation limit the potential of your resin printer. Take advantage of the benefits of a proper enclosure and unleash the full potential of your machine today. If you’re unsure about how to get started, make sure to read our comprehensive guide on optimizing resin printer performance with proper ventilation enclosure, where we discuss tips and tricks to get the perfect setup.

“Resin Printer Enclosure Ventilation” ~ bbaz

Optimize Resin Printer Performance with Proper Ventilation Enclosure

Introduction

Resin printers have revolutionized the world of 3D printing, allowing inventors, hobbyists, and professionals to create detailed, high-resolution models. However, the resin used in these printers can emit harmful fumes throughout the printing process. To reduce the risks associated with exposure to these fumes, it’s recommended to use a ventilation enclosure to optimize resin printer performance.

What is a Ventilation Enclosure?

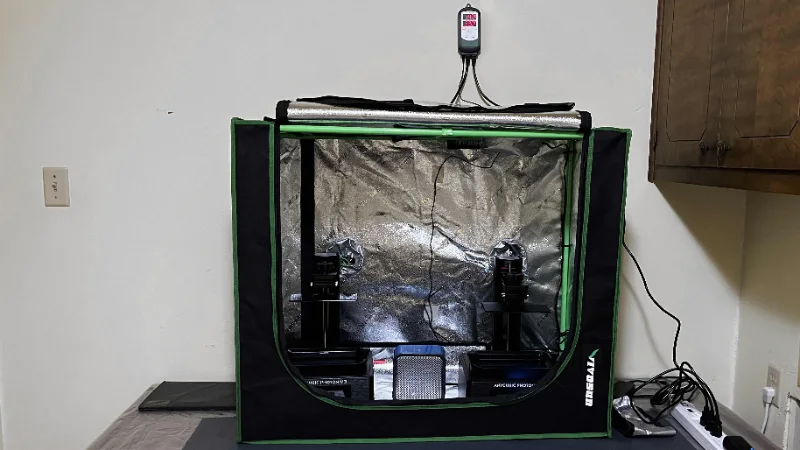

A ventilation enclosure is a specially-designed enclosure that helps protect users from the harmful fumes released during resin printing. It typically consists of an air filtration system that captures the fumes and removes them from the printer’s immediate area.

The Importance of Ventilation Enclosures

Ventilation enclosures are essential for optimizing resin printer performance because they help to reduce the risks of exposure to hazardous fumes. These fumes typically contain volatile organic compounds (VOCs) and other chemicals that can be harmful to human health.

Types of Ventilation Enclosures

There are two main types of ventilation enclosures: open and closed. Open enclosures allow for better airflow and are typically less expensive. Closed enclosures, on the other hand, provide better protection against fumes.

Open Enclosures

Open enclosures are usually made of acrylic or other clear materials. They allow for better airflow by not completely enclosing the printing area. The main disadvantage of open enclosures is that they do not offer as much protection against fumes.

Closed Enclosures

Closed enclosures, on the other hand, are typically made of metal or a high-grade plastic. They provide much better protection against fumes because they completely seal off the printing area. Closed enclosures are more expensive but they provide better protection from the hazards of printing with resin.

Benefits of Ventilation Enclosures

There are several benefits associated with the use of ventilation enclosures when printing with resin.

Health Benefits

The most significant benefit of using a ventilation enclosure is the reduction in risk of exposure to harmful fumes. These fumes can cause dizziness, headaches, and even long-term respiratory problems like asthma.

Improved Print Results

By optimizing resin printer performance through proper ventilation, users will often see improved print results. This is because the fumes emitted during the printing process can affect the final outcome of the print.

Better Environment

Ventilation enclosures also help keep the printing area cleaner by capturing any excess resin that may have dripped or spilled during the print.

Comparing Open and Closed Ventilation Enclosures

When deciding whether to purchase an open or closed ventilation enclosure, it’s essential to consider the different features and how they compare.

Airflow

Open enclosures provide better airflow than closed enclosures. However, this increased airflow can lead to an increase in exposure to harmful fumes.Closed enclosures, on the other hand, offer less airflow, but they provide better protection against fumes. The downside is that they may require additional ventilation systems to keep the printing area cool.

Price

Open enclosures are typically less expensive than their closed counterparts. However, the price can vary depending on the size and material used for construction.Closed enclosures are often more expensive than open enclosures because they provide better protection and typically require more advanced filtration systems.

Protection

Closed enclosures provide better protection against fumes than open enclosures. This is because they completely seal the printing area, preventing any fumes from escaping.Open enclosures are still beneficial, but they don’t offer the same level of protection as closed enclosures.

Conclusion

As with any type of 3D printer, it’s important to ensure that resin printers are used safely and effectively. Ventilation enclosures are a critical component of optimizing resin printer performance and minimizing the risks associated with harmful fumes.When choosing between an open or closed ventilation enclosure, it’s essential to consider the various features and how they may affect your printing experience. A high-quality ventilation enclosure will help you achieve better print results, protect your health, and create a safer working environment.

Thank you for taking the time to read about how to optimize resin printer performance with proper ventilation enclosure. It’s important to understand that when working with resin printers, safety should always be our top priority. By implementing a proper ventilation enclosure, we can ensure that we are minimizing our exposure to harmful fumes and keeping ourselves and those around us safe.

It’s easy to overlook the importance of ventilation when first starting out with resin printing, but it’s crucial to take the necessary steps to protect our health. Not only does proper ventilation help with safety, it can also improve the quality of our prints. Without proper ventilation, fumes from the resin can settle on the printed parts, causing discoloration and affecting the quality of the final product.

In conclusion, investing in a proper ventilation enclosure for your resin printer is a small but crucial step towards ensuring both safety and high-quality printing. Don’t underestimate the power of proper ventilation and the impact it can have on your health and the quality of your work. Thank you once again for taking the time to read about this important topic.

People Also Ask about Optimize Resin Printer Performance with Proper Ventilation Enclosure:

- What is a ventilation enclosure for a resin printer?

- How does a ventilation enclosure help in improving the performance of a resin printer?

- It provides proper ventilation and airflow, which helps in reducing the emission of harmful fumes and odors during the printing process.

- It helps in maintaining a constant temperature and humidity level, which is essential for the proper functioning of the printer.

- It reduces the risk of contamination and damage to the printer by creating a controlled environment.

- What are the benefits of using a ventilation enclosure for a resin printer?

- Improved print quality and accuracy

- Reduced emissions of harmful fumes and odors

- Enhanced safety and protection for the user and the printer

- Extended lifespan of the printer due to reduced risk of contamination and damage

- How do I choose the right ventilation enclosure for my resin printer?

- What are the best practices for using a ventilation enclosure with a resin printer?

- Ensure proper airflow and ventilation by using a high-quality exhaust fan and ducting system.

- Maintain a consistent temperature and humidity level inside the enclosure.

- Regularly clean and maintain the enclosure to prevent contamination and damage to the printer.

- Follow all safety guidelines and precautions when working with resin and other hazardous materials.

A ventilation enclosure for a resin printer is a specially designed box-like structure that helps in optimizing the performance of the printer by providing proper ventilation and airflow.

A ventilation enclosure helps in improving the performance of a resin printer in several ways:

Some of the benefits of using a ventilation enclosure for a resin printer are:

Choosing the right ventilation enclosure for your resin printer depends on several factors such as the size and type of the printer, the materials used for printing, and the specific requirements of your printing environment. It is recommended to consult with a professional or do thorough research before making a purchase.

Some of the best practices for using a ventilation enclosure with a resin printer are: