Printer

Maximize Efficiency with High-Quality Pad Printing Pads

Maximizing efficiency is a crucial aspect of any business operation. Time is money, after all. One way to boost productivity is by using high-quality pad printing pads. These pads provide consistent transfer of ink onto various surfaces, thereby reducing the need for costly reprints and wasted materials. With the help of quality pad printing pads, a company can produce high-quality prints quickly and efficiently, saving on time and resources.In order to ensure that your pad printing operation runs smoothly, it’s important to invest in the best equipment available. Good printing pads are essential to achieve the desired results. Lower quality pads can lead to inconsistent print quality, causing delays in the production process. On the other hand, high-quality pads ensure that each print is made perfectly, eliminating the need for costly reprints and avoiding wasted materials. This way, you can maximize your printing efficiency while minimizing costs.Taking steps to improve efficiency does not only benefit businesses from a financial standpoint, it also reflects positively on a company’s brand image. With the use of high-quality pad printing pads, a business can deliver flawless prints, impressing customers and standing out in the market. As a result, customer satisfaction and loyalty increase, and a business can enjoy long-term success.In conclusion, if a business wants to maximize its efficiency and overall output, using high-quality pad printing pads is a wise decision. Investing in durable and reliable pads can ensure consistent print quality, reducing the need for costly reprints and wasted materials. And with fewer errors and faster production times, a business can strengthen its reputation and secure a positive outlook for years to come.

“Pad Printing Pads” ~ bbaz

Maximize Efficiency with High-Quality Pad Printing Pads

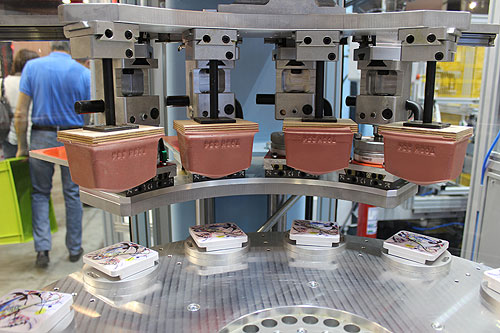

The world of printing has evolved, and many companies are seeking more convenient methods of printing. While offset printing may have been the traditional way of printing, pad printing has taken over as an efficient and cost-effective solution. Pad printing allows for high-quality printing on a variety of surfaces and textures, such as plastics, metals, and fabrics. To maximize efficiency in pad printing, high-quality pad printing pads are necessary.

What are Pad Printing Pads?

Pad printing pads, also known as silicone rubber transfer pads, are responsible for transferring ink from the printing plate to the surface being printed on. The pad picks up the ink from the plate and then transfers it in a neat and precise manner once applied onto the surface.

Importance of High-Quality Pad Printing Pads

Using high-quality pad printing pads is essential for maximizing efficiencies in the printing process. Using low-quality pads can lead to the following problems:

Problems with Low-Quality Pads |

Benefits of High-Quality Pads |

|---|---|

|

|

What Makes a High-Quality Pad Printing Pad?

A high-quality pad printing pad should have the following attributes:

- Consistency in its surface

- Good resistance to cleaning solvents

- Resistance to degradation by UV light

- Printink ability

- Steady hardness

- Good abrasion resistance

- Good compression set

- Good rebound properties

Evaluating Pad Printing Pads

When evaluating pad printing pads, it is essential to check for the following properties:

- Hardness

- Compression Set

- Rebound Properties

- Abrasion resistance

By testing these properties, you can determine if a pad printing pad is of high quality and will perform efficiently.

Choosing the Right Pad Printing Pad

Choosing the right pad printing pad depends on several factors such as:

- Type of substrate

- Type of ink

- Image size and resolution

- Temperature and humidity during printing

It is important to understand your printing requirements to choose a pad that is compatible with the substrate and ink, as well as able to produce clear and defined prints.

Maintaining Pad Printing Pads

To maximize pad efficiency, it is essential to maintain them regularly by:

- Cleaning them daily with appropriate solvents or cleaning agents

- Storing them in a dry, cool place away from direct sunlight

- Replacing them when necessary

The Bottom Line

Choosing high-quality pad printing pads is critical for maximizing efficiency and producing high-quality prints. By ensuring that you are using the right pad for your specific printing requirements, you can prevent problems and achieve exceptional results. It is essential to maintain your pads regularly to keep them in excellent condition and to replace them when necessary.

Thank you for taking the time to read about how you can maximize efficiency with high-quality pad printing pads. We hope that you found this article informative and useful in understanding the importance of using quality products to achieve the best results in your pad printing operations. As a company dedicated to providing the best printing supplies, we are committed to offering you the highest quality pad printing pads that can meet your printing needs.

At our company, we understand that different projects require different types of pads. That’s why we offer a wide range of pad printing pads that are designed to match various printing applications. Our premium printing pads are made from high-quality materials and are engineered to provide consistent ink transfers, which helps reduce waste and increase productivity. With our extensive line of high-quality printing pads, you can select the pad that is best suited for your needs, ensuring that you meet your customers’ expectations every time.

We take pride in offering our clients with quality printing solutions that can help them boost their printing efficiency well into the future. With our reliable products, top-notch service, and unparalleled industry knowledge, you are assured of complete satisfaction when you choose our company as your pad printing pads supplier. Thank you again for your interest, and we look forward to working with you in the future to help maximize your printing efficiency through using high-quality pad printing pads.

People Also Ask About Maximize Efficiency with High-Quality Pad Printing Pads:

- What is pad printing?

- Why is it important to use high-quality pad printing pads?

- How do I choose the right pad printing pad?

- What are the benefits of maximizing efficiency with high-quality pad printing pads?

- Where can I find high-quality pad printing pads?

Pad printing is a printing process that transfers ink from a silicone pad to a substrate (material to be printed on) using an engraved metal plate as the intermediary.

High-quality pad printing pads provide consistent and precise ink transfer, resulting in sharp and accurate prints. They also have a longer lifespan, reducing the need for frequent replacements and increasing overall efficiency.

When choosing a pad printing pad, consider the size and shape of the image to be printed, the type of substrate, and the ink being used. It is also important to select a pad that is compatible with the printing machine being used.

Maximizing efficiency with high-quality pad printing pads can lead to increased productivity, reduced downtime, and improved print quality. It can also result in cost savings by reducing the need for frequent pad replacements and minimizing material waste.

High-quality pad printing pads can be found through specialized printing equipment suppliers and manufacturers. It is important to choose a reputable supplier that offers a wide range of pad options and provides technical support to ensure proper pad selection and maintenance.