Printer

Mastering Screen Printing Exposure: Tips and Techniques for Perfect Results

Screen printing is a popular printing method that involves the use of stencils and ink to create designs on fabrics, paper or other materials. One critical aspect of screen printing is exposure, which determines the quality of the images printed. If you want to achieve perfect results in your screen printing projects, you need to master the art of exposure.

The good news is that with the right tips and techniques, it is possible to master screen printing exposure, whether you are a beginner or a seasoned professional. In this article, we will explore some effective strategies for achieving perfect results in screen printing exposure.

If you want to achieve optimal results when exposing screens for screen printing, you need to invest in high-quality emulsions and films. These two components play a critical role in creating a sharp and clear image. Moreover, you should also pay attention to factors such as exposure time and light source. By understanding these elements of screen printing exposure, you can optimize the process and achieve consistent and high-quality results every time.

Are you looking to take your screen printing skills to the next level? If so, mastering screen printing exposure is essential. From choosing the right materials to managing exposure times, there are various strategies and techniques you can employ to achieve high-quality results. With this guide, you can gain the knowledge and skills necessary to become a pro at screen printing exposure. So, read on to discover tips and tricks for perfecting your craft!

“Screen Printing Exposure” ~ bbaz

Mastering Screen Printing Exposure: Tips and Techniques for Perfect Results

Introduction

What is Screen Printing Exposure?

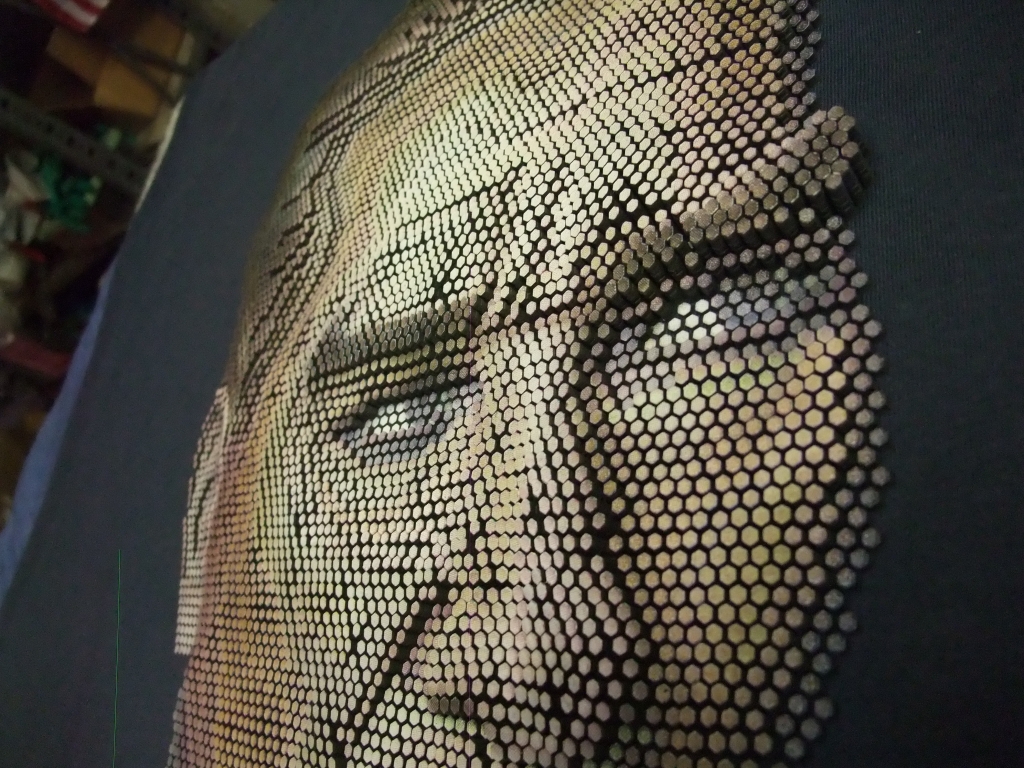

Screen printing exposure is the process of exposing a light-sensitive emulsion-coated screen to UV light, which hardens the emulsion around the stencil. It locks the image on the screen, ensuring that it remains in place during printing. The exposure time depends on several factors, such as the thickness and type of emulsion, the color of ink, and the mesh count of the screen.

Why is it Important to Master Screen Printing Exposure?

The Different Types of Lighting Used for Screen Printing Exposure

There are several types of lighting used for screen printing exposure. Each has its pros and cons, and the best choice depends on individual preferences, budget, and convenience.

Fluorescent lighting

HID or Metal halide lamps

LED lights

The Importance of Proper Screen Cleaning Before Exposure

Before Exposing images, the screen`s surface should be spotlessly clean so that no dust or stains will affect the image’s quality. The screen must be cleaned thoroughly to remove any dirt or debris that may interfere with the stencil’s proper adhesion. The screen should be free from any excess emulsion, ink residue or dust using an approved cleaning solution and a spray bottle.

Proper Screen Tension

The Importance of Fabric Selection

It’s essential to select the right fabric when screen printing to ensure that the image will come out as intended. Different fabrics require different mesh counts. For example, meshes with finer threads are used for printing detailed designs and fine art prints.

The Right Exposure Time

Finding the Right Exposure Time

The exposure time finding involves testing and adjusting time until the ideal outcome is achievable. A step test can be conducted to achieve this goal by dividing the film into various sections, each with different times. The time required for the finest section to produce solid results is used as a baseline for the next prints.

Conclusion

Screen printing exposure is an essential part of the screen printing process. The right exposure time leads to sharp corners, fine lines, and consistent images, while incorrect or subpar exposure times will sabotage the efforts and waste resources. Proper screen cleaning, fabric selection, tension, and lighting are all critical factors that come together in pursuit of the perfect print. Achieving the optimum outcome is possible with the right tools, techniques, and a willingness to put in the effort required.

Mastering Screen Printing Exposure: Tips and Techniques for Perfect Results

Thank you for reading our article on mastering screen printing exposure. We hope that you have gained valuable insights and tips on how to achieve perfect results with this technique.

Screen printing can be a challenging process but with the right knowledge and techniques, you can produce amazing prints that are sure to impress. We have covered important topics in this article such as choosing the right emulsion, calculating exposure times, and troubleshooting common issues.

We hope that this article has been informative and helpful in your screen printing journey. We encourage you to keep learning and experimenting because that’s the best way to improve your craft. Remember, practice makes perfect, so keep pushing yourself to try new things and take on new challenges. Thank you again for stopping by, and we wish you all the success in your future screen printing endeavors.

People also ask about Mastering Screen Printing Exposure: Tips and Techniques for Perfect Results:

- What is screen printing exposure?

- What are the benefits of mastering screen printing exposure?

- What equipment do I need for screen printing exposure?

- How do I determine the correct exposure time?

- What are some tips for achieving perfect results in screen printing exposure?

- Can I use natural sunlight for screen printing exposure?

- What are some common mistakes to avoid in screen printing exposure?

- Screen printing exposure is the process of curing an emulsion-coated screen with UV light to create a stencil for printing. This process involves exposing a screen coated with a light-sensitive emulsion to UV light to harden the emulsion and create a stencil. The stencil can then be used to print designs onto various surfaces, including fabric, paper, and metal.

- The benefits of mastering screen printing exposure include: creating sharp, detailed prints with consistent results, reducing waste by avoiding underexposure or overexposure, and saving time and money by minimizing the need for re-prints or touch-ups.

- The equipment needed for screen printing exposure includes: a light source (such as a UV exposure unit or natural sunlight), a screen coated with a light-sensitive emulsion, a transparency film with the design to be printed, and a vacuum table or weight to ensure even contact between the screen and the transparency.

- To determine the correct exposure time, consider factors such as: the type of emulsion used, the mesh count of the screen, the thickness of the emulsion coating, and the strength of the light source. Conduct a series of test exposures with varying time intervals to determine the optimal exposure time for your specific setup.

- Some tips for achieving perfect results in screen printing exposure include: ensuring that the screen and transparency are clean and free of debris, using a consistent distance between the light source and the screen, and timing the exposure accurately to avoid under- or overexposure.

- While natural sunlight can be used for screen printing exposure, it may not be as reliable or consistent as a UV exposure unit. Factors such as cloud cover, time of day, and location can impact the strength and quality of natural sunlight, making it more difficult to control the exposure time and achieve consistent results.

- Common mistakes to avoid in screen printing exposure include: underexposure or overexposure, uneven contact between the screen and the transparency, using an incorrect exposure time for the type of emulsion or mesh count, and failing to properly clean and maintain the equipment.