Printer

Find the Perfect Print with Our 160 Mesh Screen Printing Supplies

Do you want to elevate the quality of your screen printing projects? Look no further as our 160 mesh screen printing supplies are the perfect solution to achieving the perfect print. With our premium quality mesh, you can easily produce detailed designs with vibrant colors that will surely captivate any viewer’s attention. Whether you are a professional printing business or a hobbyist trying to create unique designs, our supplies will help you achieve your goals.

Our 160 mesh screen printing supplies are perfect for creating various types of prints such as t-shirts, hoodies, bags, and many more. They are also suitable for printing on different materials such as cotton, polyester, and even nylon. Our products are made from high-quality materials which ensure long-lasting durability and maximum performance. You can trust that your prints will not fade, peel, or crack over time.

At our store, we take pride in offering a wide range of screen printing supplies that cater to the different needs and preferences of our customers. We understand that achieving the perfect print requires the right tools, that’s why we offer our 160 mesh screen printing supplies at an affordable price without compromising quality. Get yours now and see the difference it makes in your printing projects.

In summary, if you want to achieve high-quality prints with detailed designs and vibrant colors, our 160 mesh screen printing supplies are the perfect solution for you. Our products are versatile, durable, and affordable, making them the ideal choice for both professionals and hobbyists. So why settle for less when you can get the best? Visit our store today and experience the excellence of our screen printing supplies!

“160 Screen Printing Mesh” ~ bbaz

Introduction

The importance of mesh size in screen printing

What is a 160 mesh screen?

Comparison with 110 mesh screen

Comparison with 230 mesh screen

Comparison with 305 mesh screen

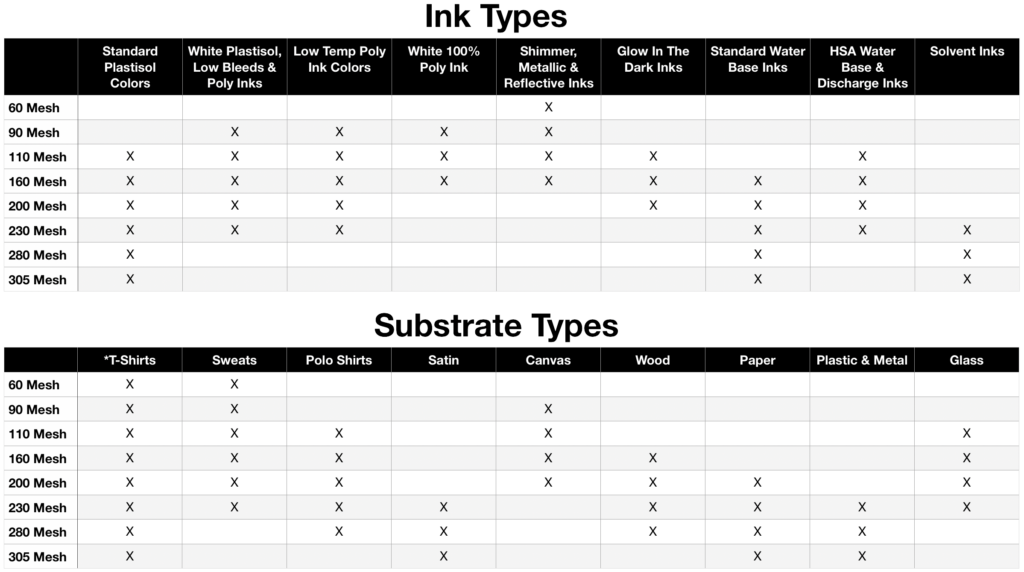

Comparison table

| Mesh Count | Best For | Drawbacks |

|---|---|---|

| 110 Mesh | Printing on dark fabrics | Limited detail and resolution |

| 160 Mesh | Standard designs with average ink amount | Not suitable for extremely detailed designs |

| 230 Mesh | Printing fine details and thin lines | Not suitable for designs requiring thick layers of ink |

| 305 Mesh | Printing high-resolution images on smooth surfaces | Requires minimum ink to pass through the screen |

Conclusion

Find the Perfect Print with Our 160 Mesh Screen Printing Supplies

Thank you for taking the time to read our article about finding the perfect print with our 160 mesh screen printing supplies. We hope you have found this information helpful and informative.

At our company, we understand the importance of finding the right supplies for your screen printing needs. Our 160 mesh screen printing supplies have been carefully selected to give you the best possible results. We offer a wide range of products to choose from, and our team is always happy to assist you with any questions or concerns you may have.

Whether you are a seasoned screen printer or just starting out, we have everything you need to achieve the perfect print. Our high-quality products, competitive prices, and exceptional customer service make us the go-to choice for screen printers across the country. So why not give us a try and see for yourself what our 160 mesh screen printing supplies can do for you?

People also ask about Find the Perfect Print with Our 160 Mesh Screen Printing Supplies:

- What is a 160 mesh screen printing supply?

- What materials can be printed using a 160 mesh screen printing supply?

- What are the benefits of using a 160 mesh screen printing supply?

- How do I choose the right ink for my 160 mesh screen printing supply?

- Do I need any special equipment to use a 160 mesh screen printing supply?

A 160 mesh screen printing supply is a type of screen that is used to print designs on various types of materials. It has 160 threads per inch, which makes it ideal for producing fine details and intricate designs.

A 160 mesh screen printing supply can be used to print on a wide range of materials, including cotton, polyester, nylon, and more. It is ideal for printing on t-shirts, sweatshirts, hats, bags, and other textiles.

Some of the benefits of using a 160 mesh screen printing supply include producing high-quality prints with fine details, achieving consistent results, and being able to print on a wide range of materials. Additionally, it is easy to clean and maintain, making it a popular choice among screen printers.

When choosing ink for your 160 mesh screen printing supply, it is important to consider the type of material you will be printing on, as well as the color and design of your print. Water-based inks are a popular choice for printing on light-colored fabrics, while plastisol inks are ideal for printing on dark fabrics.

While there are some specialized tools and equipment that can be helpful when using a 160 mesh screen printing supply, such as a squeegee and a screen stretcher, they are not strictly necessary. With a little practice and the right techniques, you can achieve great results using just your screen, ink, and a manual press.