Printer

Efficient Arc Flash Label Printing for Safety Compliance

Do you own or manage an industrial facility where safety is a top priority? Are you concerned about the safety of your employees while working with electrical equipment that has the potential for an arc flash incident? If so, then you need to ensure that you are in compliance with safety regulations by providing efficient and clear arc flash labels.

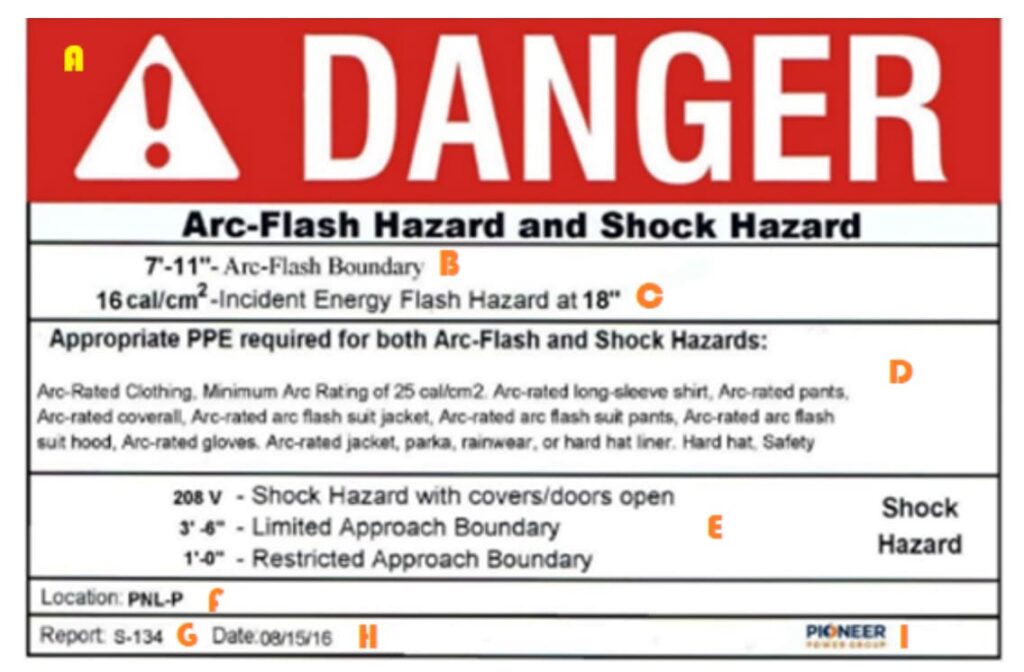

Arc flash labels are a critical component of any safety program. They provide important information such as hazard level, approach boundaries, and PPE requirements to keep employees safe while working on or near electrical equipment.

The process of printing arc flash labels can be time-consuming and complicated if you don’t have the right tools. However, with the help of modern label printing technology, you can easily and efficiently print high-quality arc flash labels that comply with safety standards in no time.

If you want to learn more about efficient arc flash label printing for safety compliance, read on to discover some helpful tips and tricks to streamline your labeling process and ensure maximum safety for your team.

“Arc Flash Label Printing” ~ bbaz

Efficient Arc Flash Label Printing for Safety Compliance

Introduction

Arc Flash Labeling Requirements

Manual vs. Automatic Label Printing

Table Comparison: Manual vs. Automatic Label Printing

| Manual Printing | Automatic Printing | |

|---|---|---|

| Efficiency | Low – time-consuming and prone to errors | High – automated and accurate |

| Customization | Limited – manual input only | High – integration with software programs |

| Cost | Low – no additional equipment required | High – initial investment in equipment required |

Durable Label Materials

GHS and NFPA Labels

Integration with Safety Management Systems

Ease of Use

Cost

Conclusion

Efficient arc flash label printing is essential for companies to comply with OSHA regulations and ensure worker safety. Automatic label printing systems offer significant advantages over manual label printing, including increased efficiency and accuracy. Employers should also use durable label materials that can withstand harsh environmental conditions, as well as integrate label printing with safety management systems for increased visibility and compliance tracking. Ultimately, investing in efficient arc flash label printing can improve safety, reduce the risk of accidents, and save lives.

Efficient Arc Flash Label Printing for Safety Compliance

Thank you for taking the time to read this article on efficient arc flash label printing. Ensuring safety compliance in the workplace is vital, and properly labeling equipment and machinery is one of the most important steps in achieving this.

By using efficient label printing methods, businesses can not only save time and money, but also promote a safer work environment. With the right tools and software, labels can be created quickly and accurately, reducing the risk of errors and confusion.

Remember, arc flash incidents can be extremely dangerous and can cause serious injury or even death. By implementing a comprehensive labeling system, businesses can mitigate these risks and ensure the safety of their employees. Thank you for prioritizing safety in your workplace.

People Also Ask about Efficient Arc Flash Label Printing for Safety Compliance:

- What is Arc Flash Label Printing?

- Why is Arc Flash Label Printing important?

- How can I print Arc Flash Labels efficiently?

- What are the benefits of efficient Arc Flash Label Printing?

- Improved Safety: Efficient Arc Flash Label Printing ensures that workers have the necessary information to avoid accidents and injuries.

- Cost-Effective: By using specialized software and printers, you can print labels quickly and easily, saving time and money on manual processes.

- Compliance: Printed labels help to ensure that you are meeting safety compliance requirements and avoiding potential penalties.

- What should I include on an Arc Flash Label?

- Equipment Name and ID

- Voltage Rating

- Short Circuit Current Rating

- Protective Device Type and Settings

- Working Distance

- PPE Requirements

Arc flash label printing is a process of printing labels that identify the potential arc flash hazards in an electrical system. These labels provide critical information to workers and help them to take necessary precautions to avoid accidents.

Arc flash label printing is important because it helps to ensure safety compliance in the workplace. The labels provide critical information about the potential hazards in an electrical system, helping workers to take necessary precautions to avoid accidents.

You can print Arc Flash Labels efficiently by using specialized software and printers designed for this purpose. These tools allow you to create custom labels quickly and easily, with all the necessary information required for safety compliance.

An Arc Flash Label should include the following information: