Printer

Revolutionize Your Screen Printing with a Dip Tank Solution

Are you tired of spending hours scrubbing ink off your screens after a printing session? Do you want to streamline your screen printing process and achieve better results? Then it’s time to revolutionize your screen printing with a dip tank solution!

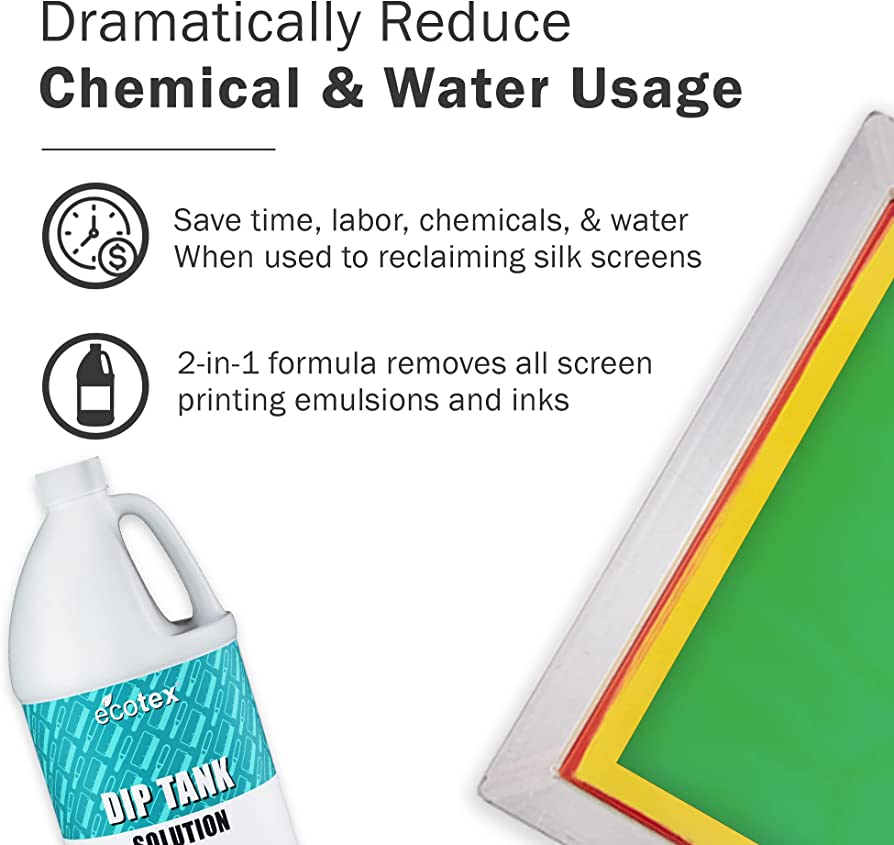

A dip tank solution is a gamechanger for screen printers. It allows you to clean your screens quickly and efficiently, without the need for harsh chemicals or scrubbing. Simply immerse your screens in the solution, let them soak, and watch as the ink dissolves away. With this innovative solution, you can save time, reduce waste, and improve the quality of your prints.

But that’s not all – a dip tank solution can also help you save money in the long run. By cutting down on the amount of time and resources needed to clean your screens manually, you can increase your productivity and profitability. Plus, the reduced use of chemicals means you’ll be doing your part for the environment too.

If you’re ready to take your screen printing business to the next level, then a dip tank solution is the way to go. So why wait? Read on to discover more about how this revolutionary technology can transform your workflow and help you achieve your goals.

“Dip Tank For Screen Printing” ~ bbaz

Revolutionize Your Screen Printing with a Dip Tank Solution

Are you tired of struggling to clean your screens after every print job? Are you searching for a better, faster method of screen cleaning that will save you time and money? Look no further than the dip tank solution. This revolutionary method of screen cleaning will take your printing process to a whole new level. In this article, we’ll explore the benefits of the dip tank solution and compare it to traditional screen cleaning methods.

What is a dip tank solution?

A dip tank solution is a container that holds a cleaning solution designed to dissolve ink and emulsion from screens. The process involves submerging screens in the solution and allowing them to soak for a predetermined amount of time. The solution breaks down the ink and emulsion, making them easy to remove with a pressure washer or hose.

The benefits of a dip tank solution

Using a dip tank solution has several benefits over traditional screen cleaning methods. These include:- Faster cleaning times: With a dip tank solution, screens can be cleaned in just a matter of minutes. This is much faster than traditional methods, which can take hours.- More thorough cleaning: Dip tanks allow for a more thorough cleaning of screens, ensuring that all ink and emulsion is removed from the mesh. This can lead to better print quality and longer screen life.- Reduced labor costs: Because dip tanks clean screens more quickly and thoroughly than traditional methods, they can save you money on labor costs. Your staff can spend more time printing and less time cleaning screens.

Comparison to traditional screen cleaning methods

Let’s take a closer look at how dip tank solutions compare to traditional screen cleaning methods.

Method

Time

Thoroughness

Labor costs

Hand cleaning

Hours

Poor

High

Pressure washing

30-45 minutes

Good

Medium

Dip tank solution

10-20 minutes

Excellent

Low

Opinion on dip tank solutions

In my opinion, dip tank solutions are a game-changer for screen printers. They offer a faster, more efficient method of screen cleaning that can save businesses time and money. While some printers may be hesitant to invest in a new piece of equipment, the benefits of dip tanks are clear. I highly recommend that businesses consider making the switch to a dip tank solution for their screen cleaning needs.

Conclusion

In conclusion, dip tank solutions are an innovative method of screen cleaning that can revolutionize your screen printing business. They offer faster, more thorough cleaning than traditional methods and can save you money on labor costs. If you’re looking for a way to streamline your screen cleaning process and improve your print quality, a dip tank solution may be the perfect solution for you.

Thank you for taking the time to read our blog about revolutionizing your screen printing with a dip tank solution. We hope that our insights and tips have helped you understand how a dip tank can drastically improve your screen printing process, and ultimately, increase your business’s productivity and profitability.

We understand that investing in a dip tank may seem daunting or unnecessary at first, but we assure you that it will be worth it in the long run. Not only will you save time and money by using a dip tank to reclaim your screens, but you will also reduce your environmental impact by minimizing your water usage and waste.

If you have any questions or concerns about incorporating a dip tank into your screen printing workflow, please do not hesitate to reach out to us. Our team of experts is here to help you find the best solution for your specific needs and goals. Thank you again for choosing to learn more about this game-changing technology, and we wish you all the best for your screen printing future.

People also ask about Revolutionize Your Screen Printing with a Dip Tank Solution:

- What is a dip tank solution for screen printing?

- How does a dip tank solution work?

- What are the benefits of using a dip tank solution?

- Time-saving: Using a dip tank solution can save you a lot of time, as it eliminates the need for manual scrubbing of screens.

- Cost-effective: By using a dip tank solution, you can extend the life of your screens, reducing the need for frequent replacements.

- Environmentally-friendly: Some dip tank solutions are formulated with eco-friendly ingredients, making them a safer alternative to harsh chemicals.

- Efficient cleaning: Dip tank solutions can effectively remove stubborn ink and emulsion stains that may be difficult to remove manually.

- Can I make a dip tank solution at home?

- Is a dip tank solution suitable for all screen types?

A dip tank solution is a cleaning solution used in the screen printing process to remove ink and emulsion from screens. It is typically made up of a mixture of chemicals, including solvents and detergents.

The dip tank solution contains solvents that break down ink and emulsion on the screen. The screen is then submerged in the solution and left for a period of time to allow the solution to work its magic. After soaking, the screen is rinsed with water to remove any remaining residue.

While it is possible to make a dip tank solution at home, it is not recommended unless you have experience working with chemicals. Commercially available dip tank solutions are formulated with the correct balance of chemicals and are safer to use.

Dip tank solutions are generally safe for use on all screen types, including mesh, polyester, and nylon. However, it is always best to check the manufacturer’s instructions before using a dip tank solution on your screens.