Printer

Revolutionize Your Mechanical Work with 3D-Printed Pulleys!

Are you tired of constantly dealing with worn-out, malfunctioning pulleys in your mechanical work? Do you wish there was a way to easily and efficiently produce high-quality pulleys without burning a hole in your pocket? Well, look no further than 3D-printed pulleys! By harnessing the power of 3D printing technology, you can revolutionize your mechanical work and say goodbye to the frustrating issues that traditional pulleys bring. Not only are 3D-printed pulleys precise and durable, but they can also be customized to fit your specific needs and requirements. In this article, we’ll delve deeper into how 3D-printed pulleys can transform your mechanical work and provide tips for optimizing their production. Plus, we’ll showcase real-life success stories of individuals and companies who have implemented these game-changing pulleys into their operations. Don’t miss out on this opportunity to take your mechanical work to the next level with 3D printing technology. Read on to learn more!

“3d Printed Pulley” ~ bbaz

Revolutionize Your Mechanical Work with 3D-Printed Pulleys!

Introduction

If you are into mechanical work, you know that pulleys are important components. They are responsible for transferring power from one point to another, and they make your work easier. Traditional pulleys have been around for a long time, but with the advent of 3D printing technology, things are changing rapidly. In this article, we look at how 3D-printed pulleys can revolutionize your mechanical work.

Source: https://tse1.mm.bing.net

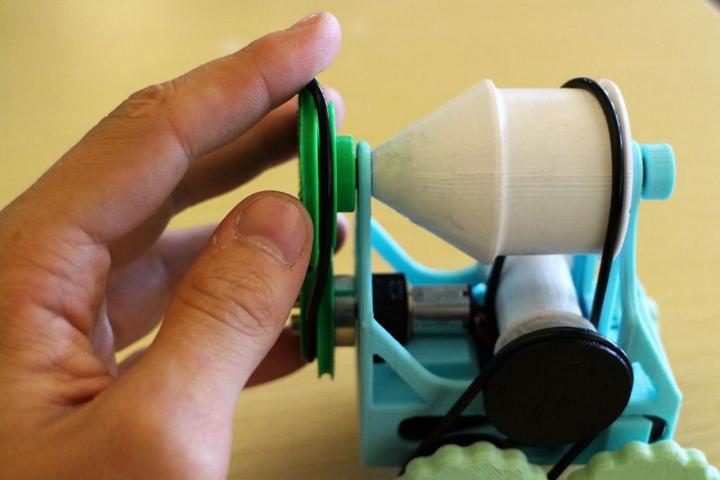

What are 3D-Printed Pulleys?

A 3D-printed pulley is a component created using a 3D printer. It is designed using software and printed using a special filament. The filament is melted and layered to create the desired shape. The resulting pulley is strong, durable, and lightweight.

Source: https://tse4.mm.bing.net

Advantages of 3D-Printed Pulleys

There are several advantages of using 3D-printed pulleys over traditional ones.

| Advantage | Traditional Pulleys | 3D-Printed Pulleys |

|---|---|---|

| Cost | Expensive to manufacture | Cheap to manufacture |

| Customization | Limited customization options | Highly customizable |

| Strength | Strong | Stronger than traditional pulleys |

| Weight | Heavy | Lightweight |

As seen in the table above, 3D-printed pulleys are cheaper to manufacture, highly customizable, stronger, and lighter than traditional pulleys.

Applications

3D-printed pulleys can be used in various applications.

Source: https://tse4.mm.bing.net

Robotics

Robotics is one of the fields that can benefit greatly from 3D-printed pulleys. They can be used to create custom robotic arms, grippers, and other components.

Automotive Industry

The automotive industry can also benefit from 3D-printed pulleys. They can be used to create custom gears, transmissions, and other components.

Aerospace Industry

The aerospace industry can benefit from 3D-printed pulleys due to their lightweight nature. They can be used to create custom gears, transmissions, and other components for aircraft and spacecraft.

Conclusion

In conclusion, 3D-printed pulleys have many advantages over traditional pulleys. They are cheaper to manufacture, highly customizable, stronger, and lighter. They can be used in various applications, such as robotics, automotive industry, and aerospace industry. If you are into mechanical work, it’s time to consider using 3D-printed pulleys.

Revolutionize Your Mechanical Work with 3D-Printed Pulleys!

Thank you for taking the time to read about how you can revolutionize your mechanical work with 3D-printed pulleys! We hope that this article has given you a better understanding of the benefits of using 3D printing to create pulleys for your machines.

Whether you are a hobbyist or a professional mechanic, 3D printing is an innovative method that can provide you with many advantages. By using 3D printing technology, you can save time and money, reduce waste, and create more complex designs that may not have been possible with traditional machining methods.

We encourage you to explore the opportunities that 3D printing can offer in your mechanical work. With a little bit of knowledge and creativity, you can easily create a customized and effective pulley system to improve your machines’ performance. Don’t forget to share your experiences with us and let us know how 3D printing has transformed your mechanical work!

People also ask about Revolutionize Your Mechanical Work with 3D-Printed Pulleys!

- What are pulleys used for in mechanical work?

- How can 3D-printed pulleys revolutionize mechanical work?

- What materials can be used to 3D-print pulleys?

- Are 3D-printed pulleys as strong as traditional metal pulleys?

- What equipment is needed to 3D-print pulleys?

Pulleys are used to transmit power and motion between rotating shafts, typically in machinery or vehicles.

3D-printed pulleys offer several benefits over traditional metal pulleys, including cost-effectiveness, customizability, and reduced weight. They also have the potential to improve performance and efficiency in mechanical systems.

Common materials used to 3D-print pulleys include PLA, ABS, and nylon. However, the specific material used will depend on the application and desired properties of the pulley.

While 3D-printed pulleys may not be as strong as metal pulleys in all cases, they can still be designed and printed to meet the required specifications for a given application. With proper design and material selection, 3D-printed pulleys can offer comparable strength to metal pulleys.

To 3D-print pulleys, you will need a 3D printer, appropriate software for designing and slicing the pulley model, and the necessary materials (filament). You may also need additional tools for post-processing and finishing the printed pulley.