Printer

Efficient Direct to Screen Printers for Seamless Printing Process

When it comes to printing processes, direct to screen printing is one of the most efficient and cost-effective methods available. This technique involves using a specialized printer that applies ink directly onto the printing surface. With direct to screen printers, businesses can create high-quality prints quickly and efficiently without sacrificing image clarity or integrity.

One of the key benefits of direct to screen printing is the seamless printing process it offers. Unlike traditional printing methods, which involve creating separate plates for each color layer, direct to screen printers can print multiple colors at once. This helps reduce printing errors and increases efficiency in the overall process. Not only that, but direct to screen printers are also extremely versatile and can be used on a variety of materials, including paper, textiles, and plastic.

If you’re looking for a way to streamline your printing process, investing in a high-quality direct to screen printer is an excellent choice. These machines are designed to produce crisp, clear prints with minimal fuss, allowing you to focus on other aspects of your business. Plus, with many different models available on the market, there’s sure to be a direct to screen printer that fits your unique needs and budget.

In conclusion, direct to screen printers offer significant benefits for businesses looking to improve their printing process through efficiency and quality. Whether you’re printing marketing materials or t-shirts, investing in a direct to screen printer can help you achieve your printing goals while saving you time and money in the long run. So if you haven’t already, consider making the switch to direct to screen printing today!

“Direct To Screen Printer” ~ bbaz

Efficient Direct to Screen Printers for Seamless Printing Process

Introduction

In the world of printing, there are many different methods that can be used to get an image onto a substrate. One option is direct to screen printing, which is becoming increasingly popular thanks to its efficiency and ease of use. In this article, we will compare various direct to screen printers and explore why they are such a great choice for many printing applications.

What is Direct to Screen Printing?

Direct to screen printing is a method of printing where the ink is applied directly to the screen before being transferred to the substrate. This process eliminates the need for any additional steps in the printing process, such as making screens or plates. Instead, the design is created digitally and then transferred directly to the screen using a special printer.

Comparison of Direct to Screen Printers

| Printer | Image Area | Resolution | Price Range |

|---|---|---|---|

| M&R i-Image ST | 28 x 41 | 1200 dpi | $70,000 – $80,000 |

| ROQ Hybrid | 23 x 27 | 1200 dpi | $50,000 – $60,000 |

| Kornit Avalanche HD6 | 23.5 x 43.3 | 600 dpi | $200,000 – $250,000 |

Advantages of Direct to Screen Printing

No Additional Steps Needed

One of the main advantages of direct to screen printing is that no additional steps are needed in the printing process. This means that you can get your prints done faster and with less effort.

High Quality Prints

Direct to screen printers are known for creating high-quality prints. The ink is directly applied to the screen, which means that every detail is captured perfectly. This is why it’s a popular choice for applications like t-shirt printing and product labels.

Faster Turnaround Times

Because direct to screen printing eliminates the need for additional steps, it’s possible to get your prints done faster. This is especially important if you need to meet tight deadlines.

Cost-Effective

While direct to screen printers can be expensive, they are ultimately a cost-effective option in the long run. You won’t need to purchase screens or plates for every print job, which will save you money over time.

Conclusion

Direct to screen printing is a fast and efficient method of printing that is becoming increasingly popular in many industries. While it may require an initial investment, the benefits of this technology are clear. Direct to screen printers create high-quality prints, have faster turnaround times, and are ultimately cost-effective. If you’re in the market for a new printer, consider investing in a direct to screen option.

Efficient Direct to Screen Printers for Seamless Printing Process

Before we finally close this article, we would like to express our gratitude for taking the time to read about efficient direct to screen printers. We hope that the information we have shared with you has been helpful in providing a comprehensive understanding of seamless printing processes.

As we’ve mentioned earlier, direct to screen printing is a cost-efficient way to produce high-quality prints compared to other traditional printing methods. Its ability to streamline the printing process cuts down on any unnecessary costs and production time.

With the right direct to screen printer, you can guarantee immaculate prints without compromising on quality or speed. And at the end of the day, that’s what most companies and printing businesses strive for; producing exceptional results quickly and effectively.

Thank you again for reading through this article. We hope that you found it informative and engaging, and that you’ll be able to apply what you’ve learned to improve your printing process. Happy printing!

People Also Ask About Efficient Direct to Screen Printers for Seamless Printing Process:

- What is direct to screen printing?

- What are the benefits of direct to screen printing?

- What should I consider when choosing a direct to screen printer?

- What are some of the best direct to screen printers on the market?

- How can I optimize my direct to screen printing workflow?

Direct to screen printing is a process where the design is printed directly onto a mesh screen, which is then used to transfer the image onto the substrate. It eliminates the need for film positives and produces high-quality prints with sharp details and vibrant colors.

Direct to screen printing offers several advantages over traditional screen printing methods. It reduces production time and costs by eliminating the need for film positives and exposing screens. The process also allows for more precise registration and produces high-quality prints with excellent ink coverage and color vibrancy.

When selecting a direct to screen printer, consider factors such as print speed, image resolution, ink compatibility, and ease of use. Look for a printer that can handle a wide range of substrates and has advanced features like automatic cleaning and calibration to ensure a seamless printing process.

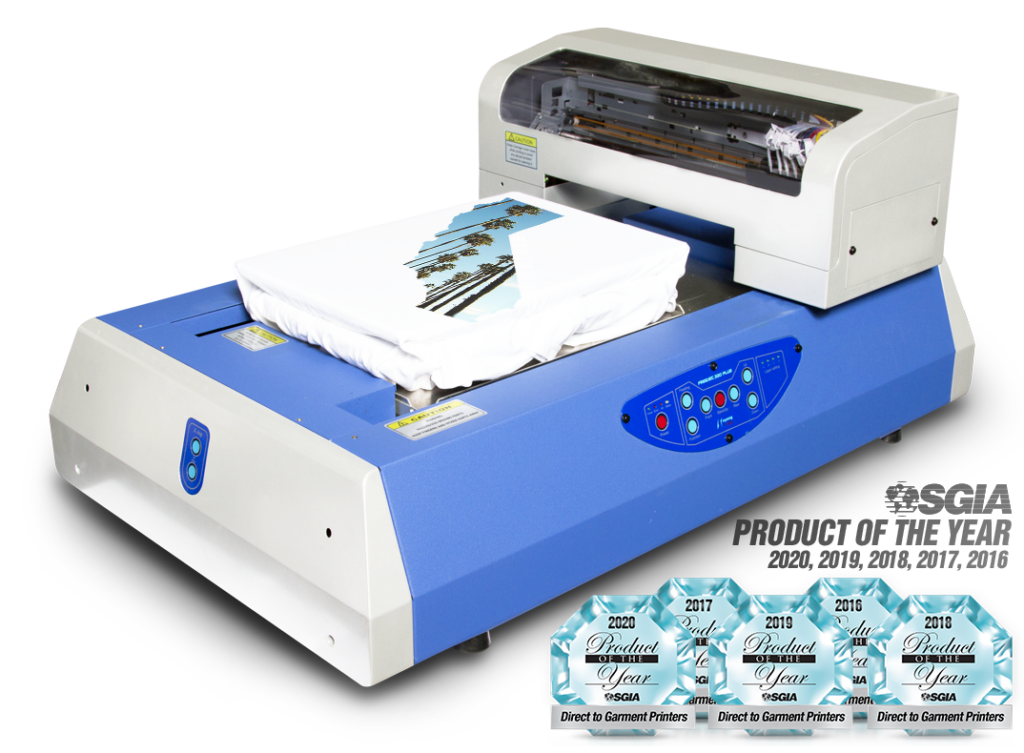

Some of the top direct to screen printers include the M&R i-Image S, ROQ Hybrid, Kornit Avalanche HDK, and Aeoon Kyo Hybrid. These printers offer advanced features like high-resolution imaging, fast printing speeds, and compatibility with various inks and substrates.

To optimize your direct to screen printing workflow, invest in a pre-press system that automates tasks like image preparation, color separation, and screen exposure. Use high-quality inks and substrates, and regularly maintain and calibrate your equipment to ensure consistent and accurate results.