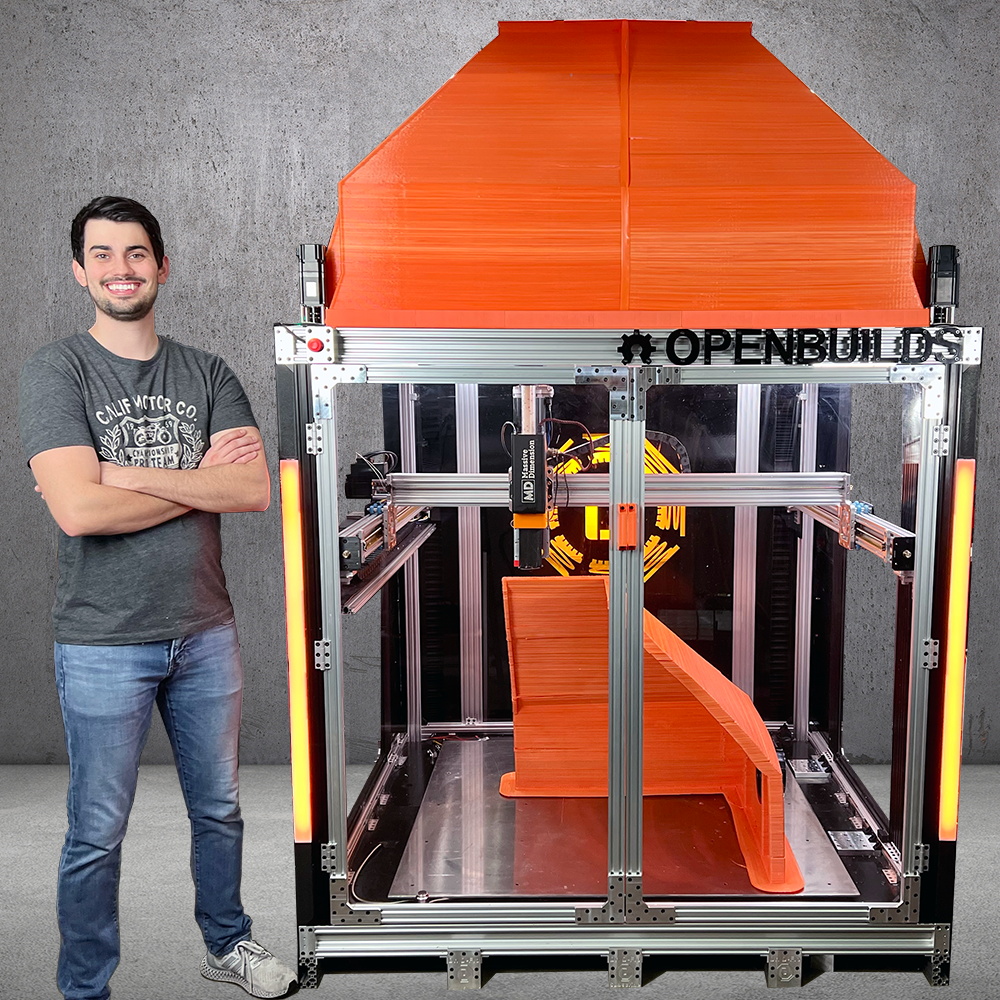

Printer

Build Your Own Large Format 3D Printer with These DIY Tips!

Are you fascinated by large-format 3D printers but don’t want to spend a fortune buying one? Well, the good news is that you can build your own DIY 3D printer that can print objects as big as you want. All you need is some technical know-how and the right tools to get started.

Building a large-format 3D printer from scratch may seem like a daunting task, but with the right guidance and tips, you can do it with ease. In this article, we provide a comprehensive guide on how to build your own large-format 3D printer step by step. We share some insightful tips and tricks, including the necessary parts and accessories that you’ll require for this project.

Whether you’re a professional engineer or just an enthusiast, building your own large-format 3D printer is a rewarding venture that can help you improve your skills and creativity. By taking up this challenge, you will have the opportunity to learn new technical skills and possibly save some money while at it.

If you’re looking for a fun and engaging way to unleash your creative talents, building your own large-format 3D printer could be the perfect DIY project for you. So, don’t hesitate any longer, read this article to the end, and take the first step towards building your very own 3D printing machine!

“Diy Large Format 3d Printer” ~ bbaz

Introduction

The world of 3D printing has been growing at a rapid pace, and large format 3D printing is becoming increasingly popular. While commercial large 3D printers may be quite expensive, some makers have found ways to create their own DIY version. In this article, we will discuss some tips on how to build your own large format 3D printer.

What is a large format 3D printer?

Large format 3D printers are machines that can print objects on a larger scale than traditional 3D printers. Generally, a large format 3D printer has a build volume of around 300x300x300mm or larger. These machines require more space, time, and materials, but they can produce larger and more complex objects.

The benefits of building your own large format 3D printer

There are several benefits to building your own large format 3D printer. Firstly, it can save you money, as commercial large format 3D printers can be quite expensive. Additionally, building your own machine allows you to customize it to your specific needs and preferences. You can also gain valuable experience and knowledge about how 3D printers work by building your own machine.

Choosing a frame design

One of the first decisions you will need to make is what type of frame to use for your 3D printer. There are many different designs to choose from, including aluminum extrusion, plywood, acrylic sheets, and more. Each material has its own advantages and disadvantages in terms of stability, weight, and cost.

Building the mechanics

The next step is to build the mechanics of the 3D printer. This includes the Z-axis guide rails, the X and Y-axis motors, the extruder, and the filament feeder. Many DIY makers prefer to use linear rails or bearings for a smoother movement of the print head.

Choosing the right electronics

Choosing the right electronics is critical for the success of your DIY 3D printer. You will need to select the right controller board, power supply, and wiring to ensure that your printer runs smoothly and efficiently. Many makers opt for open-source electronics such as RepRap or RAMPS for this.

Using the right software

Choosing the correct software is necessary for creating and printing designs on your 3D printer. While there are many options available, some popular software includes Cura, Simplify3D, and Repetier-Host. It is important to learn how to use these programs to get the most out of your printer.

Assembling and testing

After all the components have been selected and assembled, it’s time to test your 3D printer. Make sure to calibrate everything correctly, from the extruder to the X/Y/Z-axis. Once calibration is complete, print simple models to test if everything is working properly.

The cost of building a DIY large format 3D printer

The cost of a DIY large format 3D printer depends on the materials, components, and tools used. But building one from scratch will still cost less than buying a commercial large format 3D printer. Some makers have reported costs ranging from $500 to $2000 or more, depending on the quality and size of the machine.

Pros and cons of building your own large format 3D printer

Building your own large format 3D printer has its advantages and disadvantages. On the plus side, you will save money and gain valuable knowledge about 3D printing. You can also customize the machine to suit your specific needs. On the downside, it requires time, effort, and skill. You will also have to deal with any problems or errors that may arise during the building process.

Conclusion

Building your own large format 3D printer can be a rewarding and challenging experience. With the right materials, components, and tools, it is entirely possible to create a high-quality machine at a fraction of the cost of a commercial one. However, it does require dedication, patience and some skills. If you are up for the challenge, follow our DIY tips and take the first steps to build your own large format 3D printer.

Build Your Own Large Format 3D Printer with These DIY Tips!

Thank you for taking the time to read this article on building your own large format 3D printer. We hope that you have found the tips and tricks provided in this article helpful in your pursuit of building your very own 3D printer from scratch. As you may have learned, building a 3D printer can be a challenging and time-consuming task, but with the right information and tools, it’s definitely possible.

If you’re still struggling with any part of the build process or have any questions, don’t hesitate to reach out to our team for further guidance. We’re always eager to support DIY enthusiasts and makers like yourselves and want to help you achieve your goals.

The possibilities are endless when it comes to building your 3D printer, and with patience and perseverance, you can create a functional and custom machine that meets your specific needs. We wish you the best of luck on your journey and hope to see your successful builds in the near future!

People also ask about Build Your Own Large Format 3D Printer with These DIY Tips!

- What advantages does building my own large format 3D printer offer?

- What are some key components I need to build a large format 3D printer?

- How difficult is it to build a large format 3D printer?

- What are some common challenges I may face when building my own large format 3D printer?

- Where can I find resources to help me build my own large format 3D printer?

Building your own large format 3D printer offers the advantage of customization, allowing you to tailor your printer to your specific needs and preferences. It also provides a cost-effective option for those on a budget.

Some key components you will need include a frame, motors, extruder, hotend, bed, power supply, and electronics (such as a RAMPS board).

The difficulty level of building a large format 3D printer can vary depending on your experience and skill level. However, with the right resources and guidance, it is a manageable DIY project.

Some common challenges include calibration issues with the bed and extruder, wiring and electronics problems, and troubleshooting software errors.

There are a number of online communities and forums dedicated to 3D printing, where you can find information and advice from experienced makers. Additionally, there are many tutorials and guides available on the web.