Printer

Calculating Your Screen Printing Costs Made Easy

Are you tired of constantly guessing how much your screen printing projects will cost? If so, it’s time to make your life a little bit easier and learn how to calculate your screen printing costs like a pro. Don’t worry, it’s not as difficult as it sounds, and the benefits of learning this essential skill are invaluable.

Whether you’re a small business owner or a freelance designer, knowing how to calculate your screen printing costs will help you create accurate quotes for your clients or set competitive prices for your products. Not only will this increase your professionalism and credibility, but it will also save you time and money in the long run.

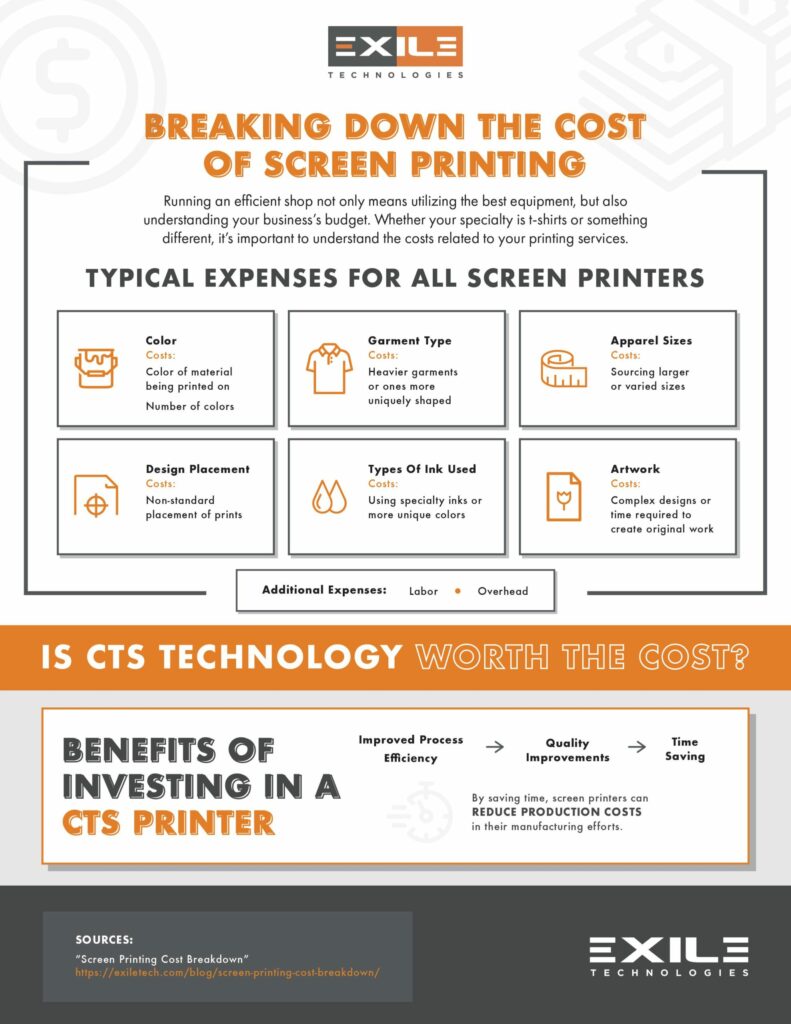

So, where do you start? The good news is that there are plenty of online resources and tools available to help you with the calculations. You’ll need to consider factors such as the number of colors, the type of ink, the size and quantity of the order, and the cost of the materials. By plugging these numbers into a reliable screen printing calculator, you’ll be able to get an accurate estimate in just a few minutes.

If you’re ready to take your screen printing business to the next level, it’s time to start calculating your costs like a pro. By mastering this crucial skill, you’ll be able to provide your clients with accurate quotes, set competitive prices for your products, and ultimately, grow your business. So, what are you waiting for? Start learning today!

“Screen Printing Cost Calculator” ~ bbaz

Calculating Your Screen Printing Costs Made Easy

Screen printing is a popular method of printing designs onto garments, but calculating the cost involved can be challenging. This article will outline a few methods for calculating your screen printing costs and help you decide which one is best for your business.

Traditional Method vs. Digital Method

The traditional method of screen printing involves designing stencils on mesh screens and layering the ink onto the garment. In contrast, digital screen printing uses a computer to create the design and then prints it directly onto the material. While these methods may vary in time required and quality of print

Traditional Method

Despite being a more labor-intensive method, traditional screen printing produces high-quality prints with saturated colors and crisp edges. This method is particularly useful when printing large batches of garments or larger designs that require specific color matching.

Digital Method

The digital screen printing process allows for faster printing times compared to traditional methods, but the quality of the print may not be as high. Additionally, the type of garment used may affect the quality of the print too. Therefore this method is more suited for small batches of garments or for designs with a limited number of colors

Cost Calculation

The cost calculation involves determining the amount of material and labor involved in creating the final product. Below are some essential factors you want to consider when calculating the costs:

Material Costs:

Besides the fabric of the garment, other materials involved include ink, stencil materials, and screens. The cost of these materials will increase based on volume.

Labor Costs:

Labor costs involve the cost of printing, cleaning, and coating the screens. In traditional screen printing, labor costs can be higher because of the stenciling process needed. Again, the cost will increase according to the volume of products you plan to produce.

Comparing Methods and Costs

To calculate which method of screen printing is better suited to your business, you need to compare their respective costs. Here is an example:

| Traditional | Digital | |

| Material Costs | $25.00 | $15.00 |

| Labor Costs | $50.00 | $20.00 |

| Total Cost | $75.00 | $35.00 |

As you can see from this example, digital screen printing is significantly cheaper than traditional screen printing. However, bear in mind the durability of the print and quality of the colors.

Conclusion

In conclusion, screen printing is a popular method of printing designs onto garments. To calculate the cost accurately, there are specific factors you should consider, such as labor and material costs. Choosing between traditional and digital screen printing methods depends on your budget or the number of items you plan to produce. The table comparison shows that digital screen printing is the cheaper option overall, but keep in mind that quality depends on factors like materials used and garment choice.

Calculating Your Screen Printing Costs Made Easy

Thank you for taking the time to read our article on calculating your screen printing costs. We hope that you found it informative and useful in your screen printing endeavors. As we mentioned in the article, calculating your costs is an essential part of running a successful screen printing business. By accurately determining your expenses and profit margins, you can make sure that you are pricing your products competitively while still making a profit.

If you have any questions or comments about the information presented in this article, please don’t hesitate to reach out to us. Our team of screen printing experts is always happy to share their knowledge and help others succeed. Additionally, if you have any suggestions for future blog topics, we would love to hear them. We want to make sure that we are providing the most relevant and valuable content to our readers.

Once again, thank you for visiting our blog and taking the time to read our article. We hope that you come back soon for more valuable insights and tips on all things screen printing. Good luck with your business and happy printing!

Calculating Your Screen Printing Costs Made Easy

- What factors affect screen printing costs?

- The number of colors used in the design.

- The quantity of items being printed.

- The type of garment or material being printed on.

- The complexity of the design.

- How can I calculate my screen printing costs?

- Determine the number of colors in your design.

- Calculate the cost of each garment/material.

- Add the cost of any set-up fees or artwork charges.

- Multiply the total by the quantity of items being printed.

- Divide the total by the number of colors in the design.

- Is it cheaper to print on lighter or darker garments?

- What is the average turnaround time for screen printing orders?

- Can I save money by ordering in bulk?

Printing on lighter garments is generally cheaper because it requires fewer ink layers to achieve the desired color. However, if you want a specific color to show up on a darker garment, additional ink layers may be necessary, which can increase the cost.

The average turnaround time for screen printing orders varies depending on the printer and the quantity of items being printed. Typically, orders can be completed within 5-10 business days, but rush options are often available for an additional fee.

Yes, ordering in bulk can often result in lower costs per item. Most printers offer quantity discounts for larger orders.