Printer

Eliminating 3D Printing Ghosting: Tips and Techniques for Success

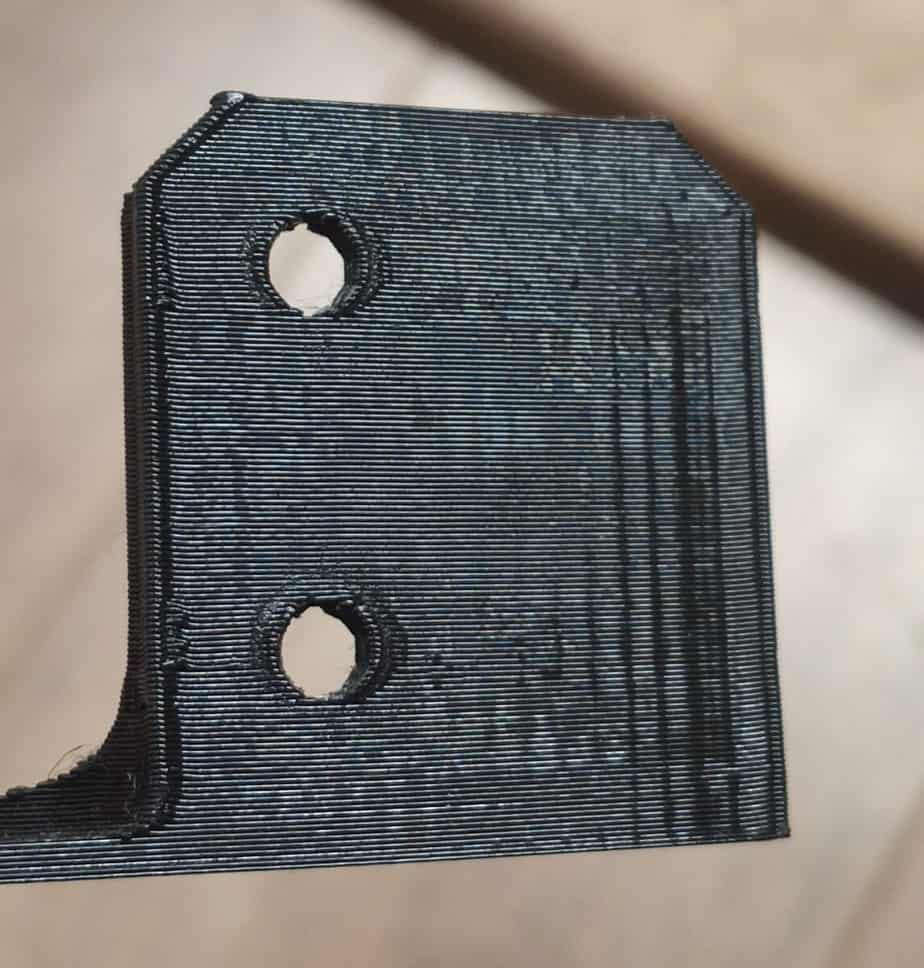

If you’re looking to create high-quality 3D prints, but you’re struggling with the problem of ghosting, then this article is for you. Ghosting can occur when your printer is not calibrated correctly, resulting in a wavy or blurry appearance on your print. Not only does it look unprofessional, but it can also compromise the structural integrity of your object. However, with a few tips and techniques, you can eliminate ghosting and achieve the perfect print every time.

One technique to try is adjusting your printer’s acceleration and jerk settings. These settings determine how quickly your printer moves and changes direction. By reducing the acceleration and jerk settings, your printer will move more smoothly, resulting in a cleaner print. Additionally, check to see if your printer’s belts are properly tightened, as loose belts can cause ghosting.

Another important factor to consider is temperature control. If your printer’s hot end is not operating at the correct temperature, it can result in inconsistent extrusion and ghosting. Make sure that you monitor your printer’s temperature levels throughout the printing process and adjust as necessary. Additionally, make sure that your filament is stored properly and is free from moisture, as wet filament can also cause ghosting.

Eliminating ghosting requires attention to detail and experimentation with different settings and techniques. Don’t give up if you don’t achieve the perfect print right away. By following these tips and techniques and putting in a little extra effort, you’ll be able to create professional-grade 3D prints that are free from ghosting and other imperfections. So why not give it a try and see the difference it can make?

“3d Printing Ghosting” ~ bbaz

Eliminating 3D Printing Ghosting: Tips and Techniques for Success

Gone are the days when 3D printing was just a fantasy. Today, it is a reality and has revolutionized the manufacturing industry. As much as it has advantages, there are some challenges that come with it, one of the significant problems being 3D Printing Ghosting. Ghosting is when the printer creates faint lines on a model caused by a slight movement of the print bed or extruder. This article discusses how you can eliminate ghosting from 3D printing.

What Causes Ghosting in 3D Printing

Ghosting in 3D printing is as a result of several factors, such as;

- Wobbly printer frame

- Non-uniform extrusion

- Loose belt tension

- Vibrations

These factors cause the layer shifts, leading to the creation of faint lines on the model.

Advantages of Eliminating Ghosting

Eliminating ghosting in 3D printing comes with several advantages, including;

- The models produced have a higher aesthetic value

- The models are more accurate and precise

- The models have stronger structural integrity

- Smooth surfaces for the model, which facilitate better printing quality

Techniques to Eliminate Ghosting in 3D Printing

Tighten Belts Tension

The first technique is ensuring the belt tension is secure. Loose belt tension causes ghosting because it creates vibrations on the axis leading to movements.

Upgrading Printer Frame

If your 3D printer’s frame is wobbly, consider upgrading it. A sturdy frame makes the printer stable, reducing movement that causes layer shifts.

Synchronize Print Speed and Filament Extrusion

To eliminate ghosting, synchronization of print speed and filament extrusion helps. It minimizes vibration, ensuring the print bed’s smooth movement for quality prints.

Update Firmware and Maintain Temperature

Ensure the temperature is controlled for quality prints free from ghosting. A firmware update helps in minimizing chances of ghosting.

Printing Flexibility

Print flexibility means you should consider the model’s orientation before printing to avoid exposure to displacement due to axial vibrations.

Table Comparison of Techniques to Eliminate Ghosting

| Technique | Advantages | Disadvantages |

|---|---|---|

| Tighten Belt Tension | Reduces vibration, stable axis movement and enhanced print quality | May not suffice if the frame is out of alignment |

| Upgrading Printer Frame | Provides stability preventing vibrations | Costly in some instances |

| Synchronize Print Speed and Filament Extrusion | Minimizes vibrations providing better print quality | Difficult when printing overhangs that require different printing speeds |

| Update Firmware and Maintain Temperature | Increased control over printing temperature, reducing chances of ghosting occurrence | Incapable of addressing axial vibrations |

| Printing Flexibility | Offers ability to change printing orientation preventing axial vibrations. | Not suitable for all model requirements |

Conclusion

Eliminating ghosting in 3D printing ensures quality prints, providing an exemplary product. The techniques discussed above are effective strategies to get rid of ghosting. While each technique has its advantages and disadvantages, it’s crucial to choose one that works best for outcome-oriented models.

References

Eliminating 3D Printing Ghosting: Tips and Techniques for Success

Thank you for taking the time to read our blog post about eliminating 3D printing ghosting. We hope that the tips and techniques shared have been helpful in your quest for successful 3D printing projects.

Ghosting is a frustrating issue that many 3D printing enthusiasts face, but with the proper knowledge and adjustments, it can be eliminated. We encourage you to experiment with different speed settings, layer heights, and temperature controls to find what works best for your printer and materials. Perseverance and patience pays off in the end!

We believe that education plays a big role in the success of any hobby or profession. That’s why we make it our mission to continuously provide helpful information to our readers. If you have any questions or suggestions for future topics, please feel free to contact us. We’d love to hear from you!

People Also Ask About Eliminating 3D Printing Ghosting: Tips and Techniques for Success

When it comes to 3D printing, ghosting is a common problem that can affect the quality of your prints. Here are some frequently asked questions about eliminating ghosting:

- What causes ghosting in 3D printing?

Ghosting occurs when the printer head moves too quickly, causing vibrations that create ripples or waves in the print. This can happen when the printer is not calibrated correctly or when the acceleration settings are too high. - How can I reduce ghosting in my 3D prints?

There are several techniques you can try to eliminate ghosting, including:- Lowering the print speed

- Adjusting the acceleration settings

- Adding dampeners to the printer frame

- Using higher-quality filament

- Is there a software solution for eliminating ghosting?

Some slicer software programs have features that can help reduce ghosting, such as coasting and pressure advance. These features adjust the printing process to prevent vibrations and improve print quality. - Can upgrading my printer help eliminate ghosting?

Upgrading your printer with a more rigid frame, better stepper motors, and other improvements can help reduce ghosting. However, these upgrades can be expensive and may not be necessary for all types of printing projects.